Since 2012, it has been common that demand exceeds the supply in liquor package industry. A lot of enterprises in this industry follow the trend of local supply which means a lot of investment or site be allocated close to the liquor suppliers. Such trend of local supply brings the opportunities for the giants in the segment, but also leads to more tough and direct competitions. How can these giants stand out?

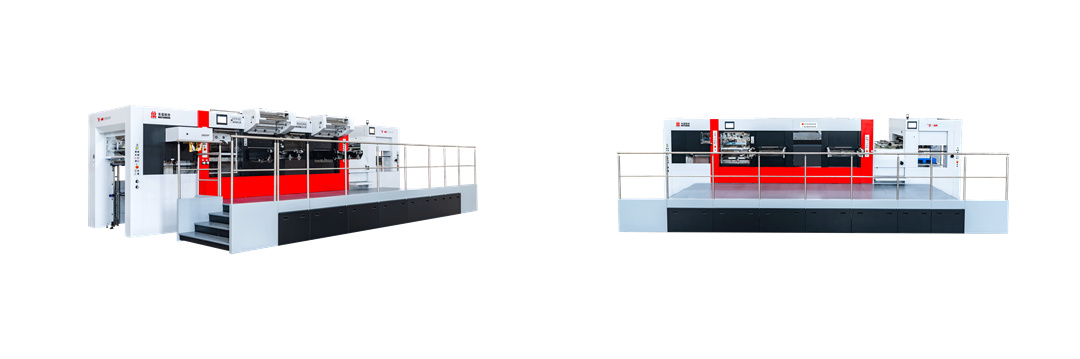

MK 21060VFF and MK 21060VS are always the common selections for Xinbangyu Packaging,MYC Group,Yutong Packaging for each of them to deal with the difficulties in competition and development although there is no any prior consultation among them. Furthermore each of them has a common recognition on application of MK equipment.

Mr. LuoXiaoBin, the Executive VP of Guizhou Xinbangyu Packaging Co., Ltd.

The greatest advantage of die cutter in MK Duopress is the much higher productivity due to 2-in-1. For example, during liquor box making, you can finish either in embossing plus embossing or embossing in full plate, die cutter with blanking altogether. The volume has been highly raised while labor cost is decreased since this equipment adopted. Up to now, there are 4 existing MK die cutters in Duopress in our plant and we foreseen that another 3 will be purchased in this year.

Mr. Zhang TianGuang, production manager from Guizhou Yutong Packaging Technology Co., Ltd.

Labor cost saving is a outstanding advantage in these two MK equipment. Now they help us a lot while we are facing the recruitment difficulties. What they produce every day is far beyond our expectation.

Mr. Cheng ZhiHong,GM of MYS Group Co. Ltd.

Our volume has been increased by 120% since we purchased MK 21060VFF. In addition to its higher productivity, the stamping position is more precise. With such equipment, the technology is no longer a problem for us and then more elegant products can be developed and produced so that we can provide even better solution for our customers.

The most important factor for MK to receive the long-time recognition from its customers is the quick reaction of MK to the market demand and customer's requirement based on its powerful R&D team. MK 21060VFF and MK 21060VS are the high-end solution typical for liquor package industry.

The stamping and die cutting technology is mature in MK and they are in line with the advanced one worldwide. Based on the patents authorized in Duopress, MK also finished the developing of the high-end equipment with different combinations of high-pressure double stamping, embossing and die cutting, which is the classic in post-press of different printing applications and widely used in such industries.

There are more than 20 enterprises, focusing on liquor package, who purchase, re-purchase the MK Duopress with high-pressure stamping, die cutter with deep embossing. MK hopes provide service for more enterprises in such industry in the future, so that MK can promote them to keep their great competitiveness regards to safety, cost, technology, productivity and delivery and lay a solid foundation for their further development.

We look forward to hearing from you. In order to respond to your message more quickly, we need some information. *These are required