An automatic die cutter with stripping function can provide a range of benefits that can improve efficiency, quality, cost-effectiveness, accuracy, and versatility. It can handle a variety of materials and shapes, making it a versatile tool for different die-cutting applications. An automated stripping function can strip off waste material and separate the finished product from the waste material automatically, which can improve production efficiency and reduce manual intervention.

The currently available die-cutting equipment in the market with waste removal function mainly includes full waste removal, semi-waste removal, full waste removal with kiss-cutting, and semi-waste removal with full waste removal.

The application of waste removal die is very extensive in automatic die-cutting units with waste removal function.

The principle is roughly as follows:

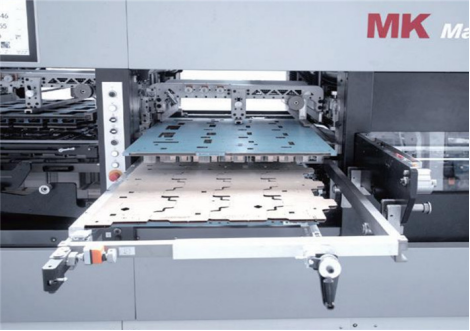

The material first enters the die-cutting part for die-cutting, then enters the lower waste removal plate of the waste removal part. At this time, the waste area in the middle of the material and the hole of the lower waste removal plate are in alignment, while the waste area at the edge of the material is outside the lower waste removal plate.

The upper waste removal plate is pressed down from top to bottom, and the waste is dropped onto the waste conveyor belt through the waste removal sheet on the upper waste removal plate, thus achieving waste removal.

The waste-free cardboard continues to move forward to the front waste removal part, and the finished product is dropped off by the front waste removal plate.

The teeth rake drags the waste at the edge of the kiss-cut to the waste conveyor belt of the machine, and then sends the waste at the edge of the kiss-cut to the waste conveyor belt to be taken away.

This is the section of the equipment that addresses wastage issues. It ejects messy scrap, the waste that collects while the cutting blades rise and fall to create their cutouts. Located behind the cutting plates, accumulating debris is quickly removed by the stripping units so that the machinery continues to work unimpeded. The waste elimination apparatus employs pneumatic power and streamlined mechanical assemblies to assure impeccable results.

Mastermatrix 106CSB is fully new developed with high automation, high intelligence, high speed and high reliability, typical for the customer who pursues the smart producing and high capacity. With the newly developed cutting unit together with Cam-Driven system and optimized gripper curve movement, the highest speed of 9000s/h is reachable.

l More accurate and convenient second-generation waste removal tool quick lock system

l Fine-tuning device with digital display

l Waste removal tool centering system

l Pneumatic lifting device for cleaning the upper frame

l The new generation suction plate device allows paper to run more smoothly and stably at high speed

MK-a professional printing equipment manufacturer and comprehensive service provider. We can provide the digital die cutting solution for short plate and short run. If you want to know more information about the laser die cutting machine, welcome to contact us, please visit our website at https://www.masterworkgroup.com/ We will be happy to help you out!

We look forward to hearing from you. In order to respond to your message more quickly, we need some information. *These are required