Blank Ejection

- Inline ejection of fault blanks without damaging

- Resorting or re-inspection of fault blanks possible

- Minimizing waste without compromising quality

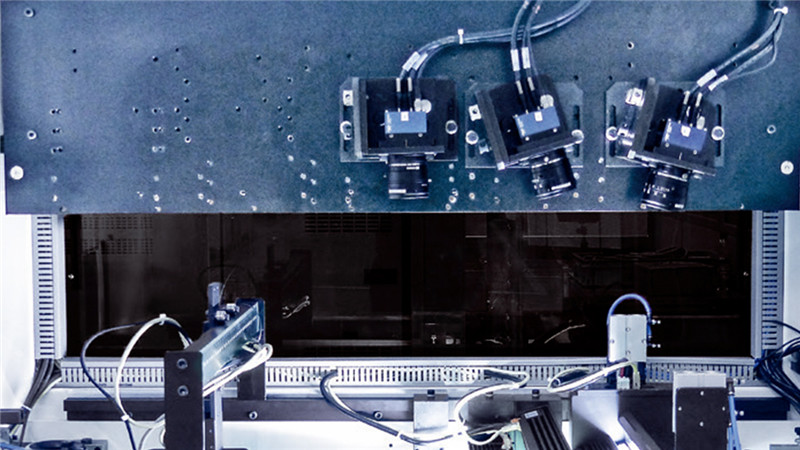

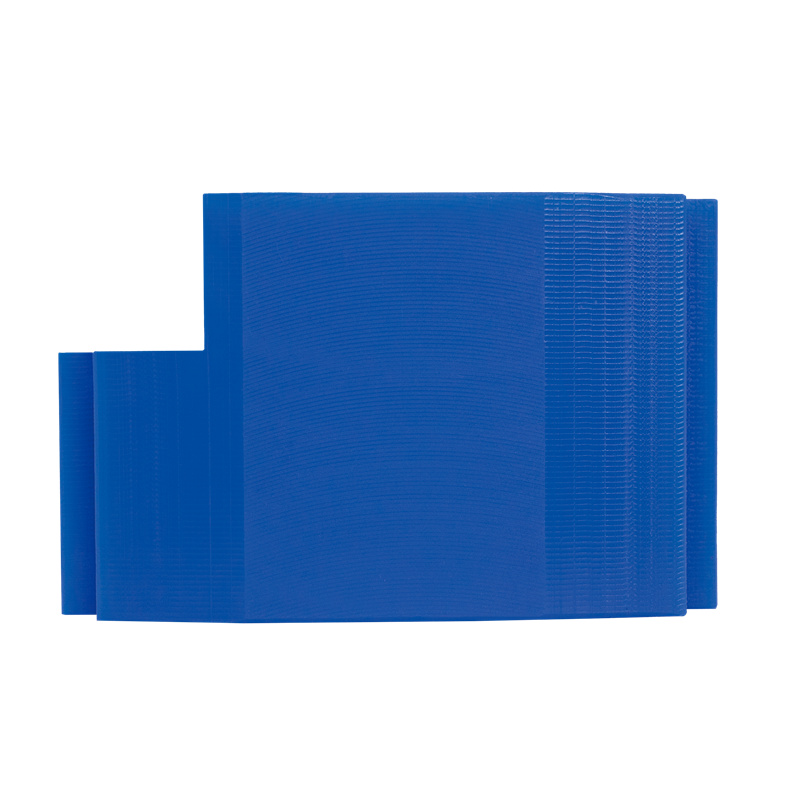

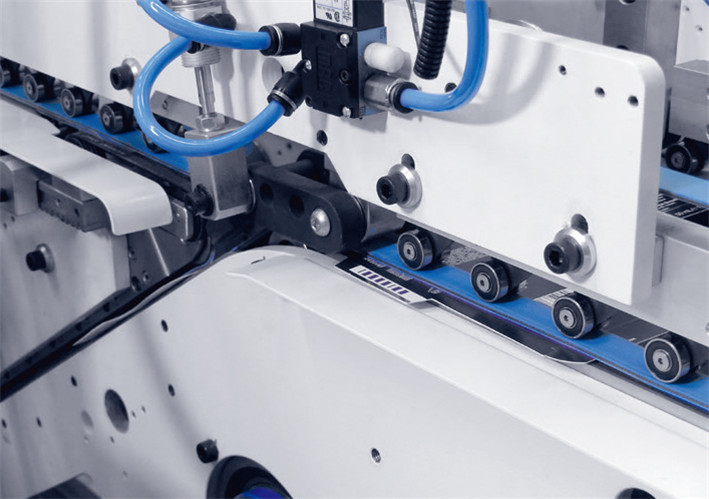

- Inspection Section

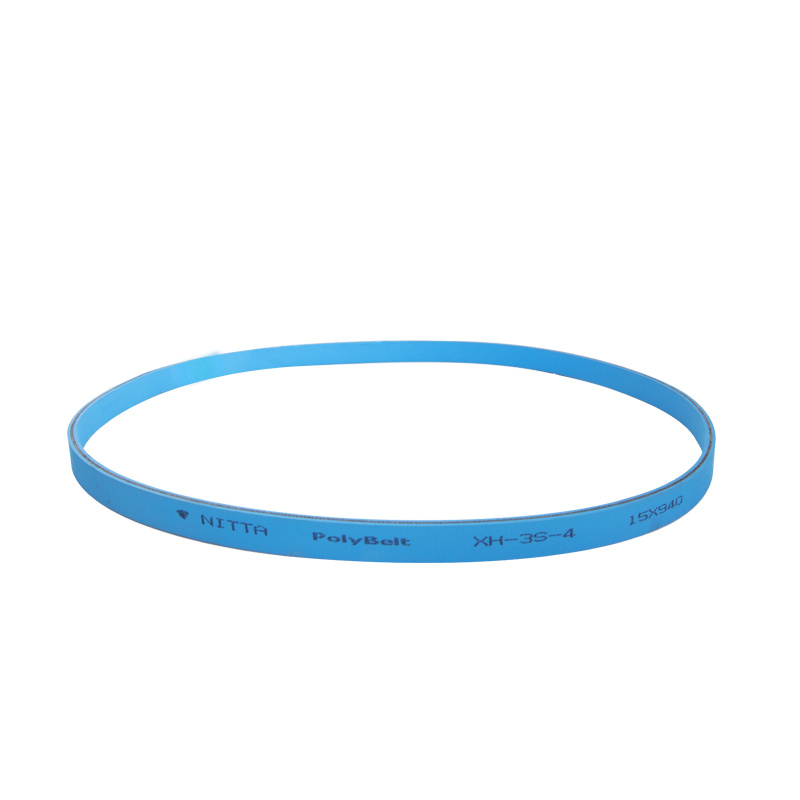

- Suction belt for safe and stable blank transport

- Space for up-to 4 cameras from above, 2 area cameras, 1 back side camera

- Easy to retrofit cameras

- Darkened window to screen user from view into active LED

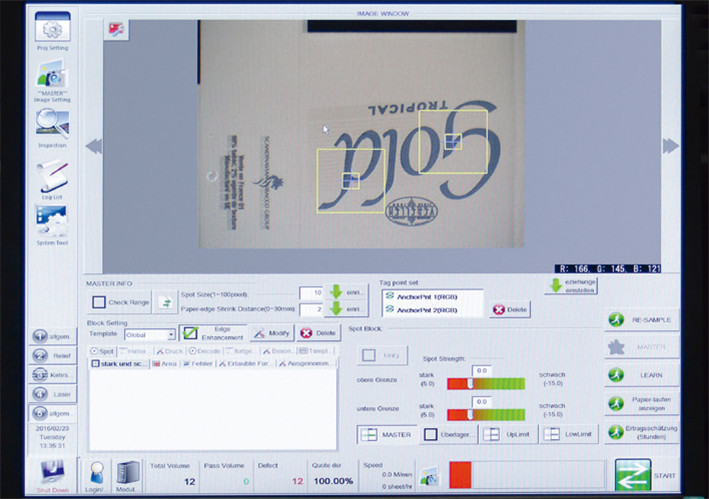

Operator Interface

- Operator terminal with 19” screen

- Easy to set up by teaching process

- Visualization of threshold setting

- Advanced setting possibilities for challenging applications.

Image Processing

- GPU+CPU Computing for fast data processing of huge image data

- Master and Slave solution

- Easy to retrofit

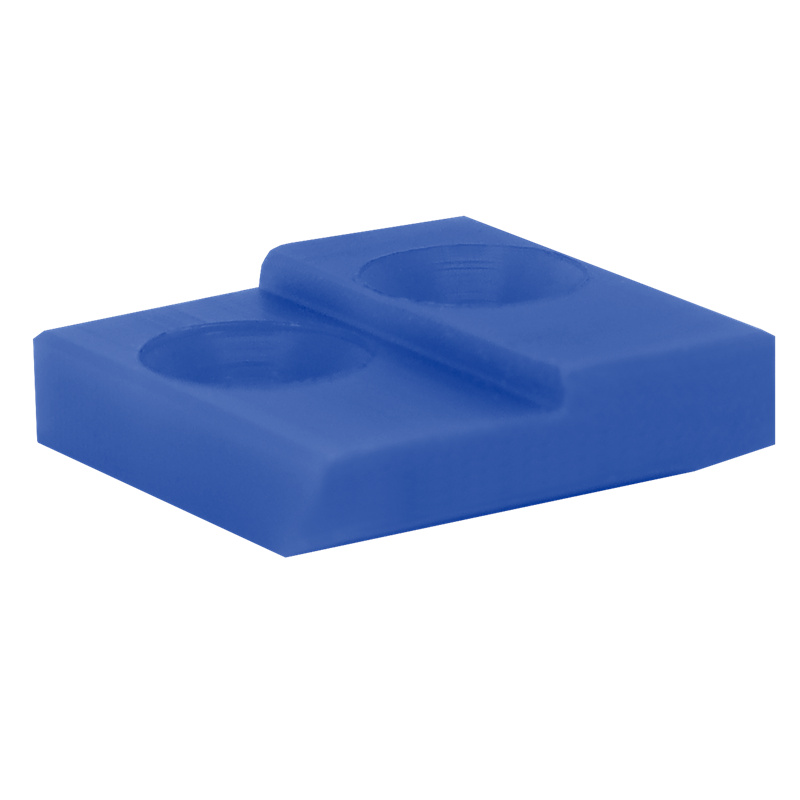

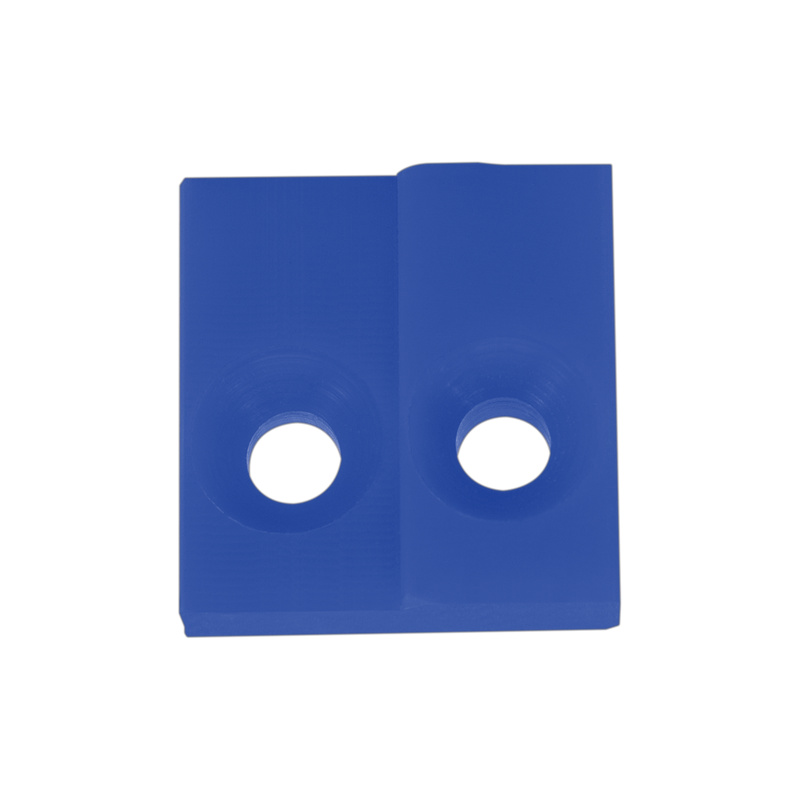

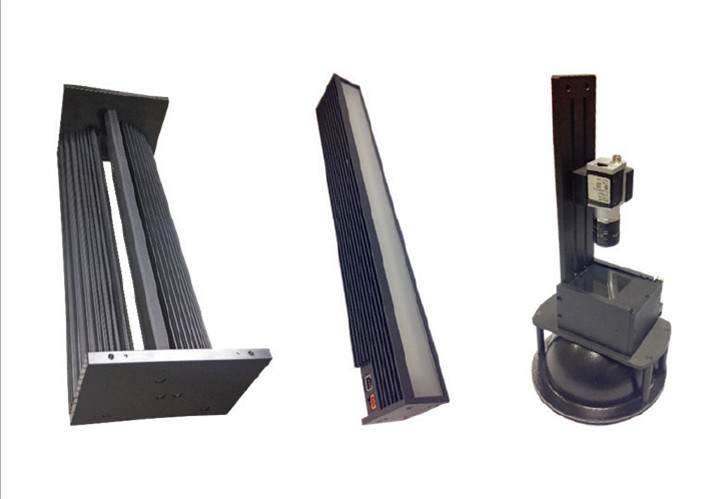

Light Sources

- A unique light dome

- Four different illumination modes applicable

- Makes metalized substrate, hot foil and hologram applications visible

- Aluminum housing keeping the light source cool without air blowers

- Adjustable light intensity

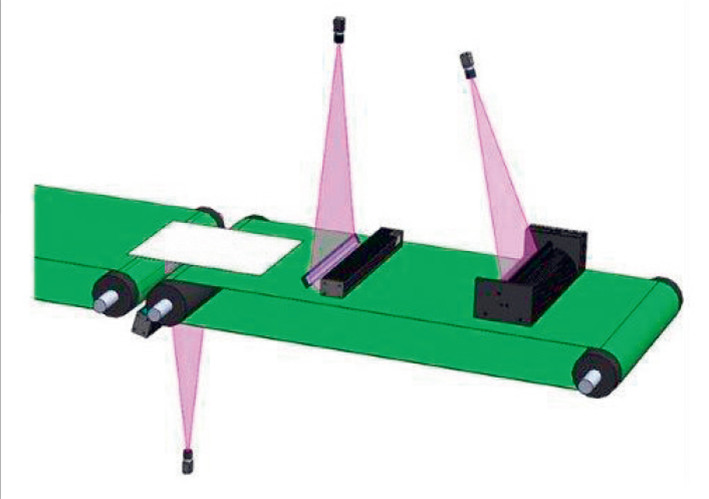

Cameras

- 4K color cameras for inspection from above in combination with a new LED-Lighting technology

- Mirror System for low-angle inspection

- 4K colorful camera for inspection of back side

- Area cameras with highest resolution for inspection of critical areas e.g. QR-Codes

| Processable material | 90 - 650 g/m2 cardboard |

| Max. speed | 300 m/min |

| Max. Output (e.g.90mm long small format package): | 80,000 s/h- 120,000 s/h |

| Max. sheet size | 420 X 350 mm |

| Min. sheet size | 70x 70 mm |

| Minimum spot size | 0.1mm2 (gray value contrast ≥ 30) |

| Minimum line size | 0.2mmx5mm (gray value contrast≥30) |

| CV | >2.5 |

| Cameras | 4K Color camera RGB |

| Pixel | 4K |

| Camera line rate | 40 k/s |

| Resolution at 420mm / 200m/min | 0.1 x0.1 mm |

| Resolution at 420mm / 300 m/min | 0.1 x0.15 mm |

| 8K mono camera B/W | |

| Pixel | 8K |

| Camera line rate | 80 k/s |

| Resolution at 420mm / 200m/min | 0.05 x0.05 mm |

| Resolution at 420mm / 300 m/min | 0.05 x0.07 mm |

| Area Camera RGB | |

| Pixel | 1.2 M |

| Camera line rate | 45 fps |

| Resolution at 420mm / 200m/min | 0.04 x0.04 mm |

| Resolution at 420mm / 300m/min | 0.04 x0.04 mm |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

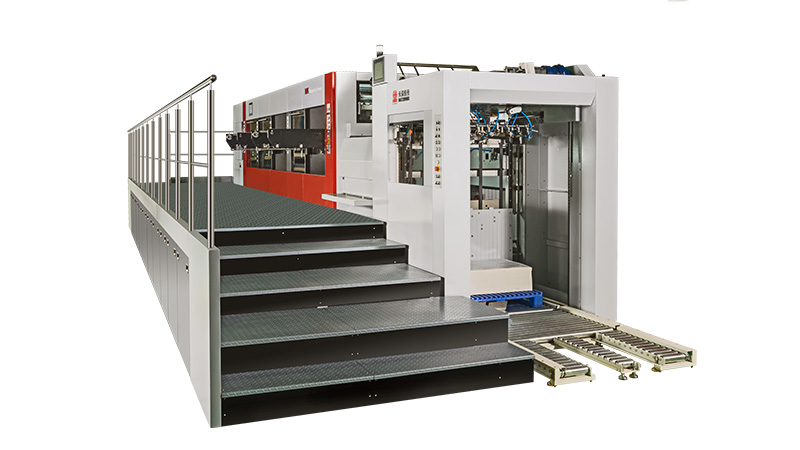

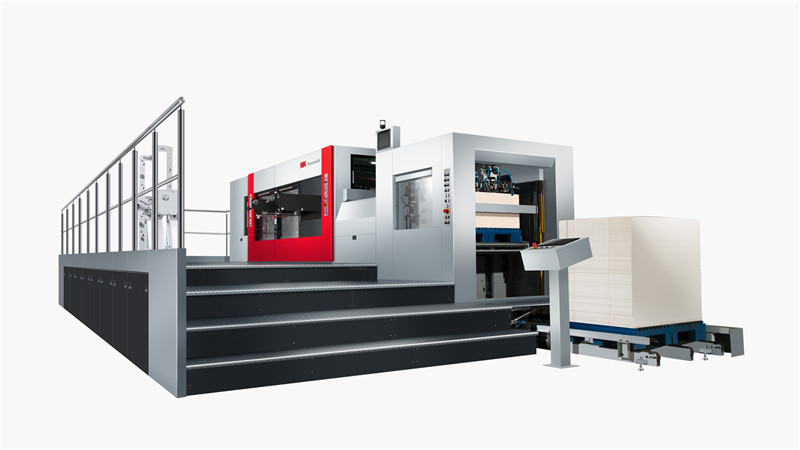

Carton Inspection Machine | MK

A carton inspection machine is an automated industrial device used in manufacturing and packaging processes to inspect and ensure the quality of cartons or boxes used to package various products such as food, pharmaceuticals, cosmetics, electronics, etc. The machine is designed to detect defects, errors or inconsistencies in carton appearance, print quality and package integrity.

In the paper printing industry, there are several types of automated inspection systems used for quality control and assurance purposes. Here are some of the most common types:

Print Register Inspection: This type of automated inspection system uses cameras and specialized software to detect and correct any color misregistration in the printed image, ensuring that the colors are correctly aligned and in register.

Defect Detection: This type of inspection system uses cameras and software to detect any defects in the printed image, such as streaks, smudges or missing ink, and remove them from the final printed product.

Barcode Verification: This type of inspection system uses specialized software and scanners to ensure that barcodes on printed materials, such as labels or packaging, are properly printed and scannable.

Web Inspection: This type of inspection system uses cameras to inspect entire rolls of paper or other materials during the printing process, detecting and identifying any defects that may affect the final product, such as holes or tears.

Optical Character Recognition (OCR): This type of inspection system uses Optical Character Recognition technology to read and verify printed text on documents, labels and packaging, ensuring accuracy and consistency.

Using a carton inspection machine can help manufacturers ensure their packaging meets quality standards, reduce the chance of defective products reaching customers, maintain brand reputation, and help comply with regulatory requirements. Automation of the inspection process also increases efficiency and consistency compared to manual inspection methods.

+

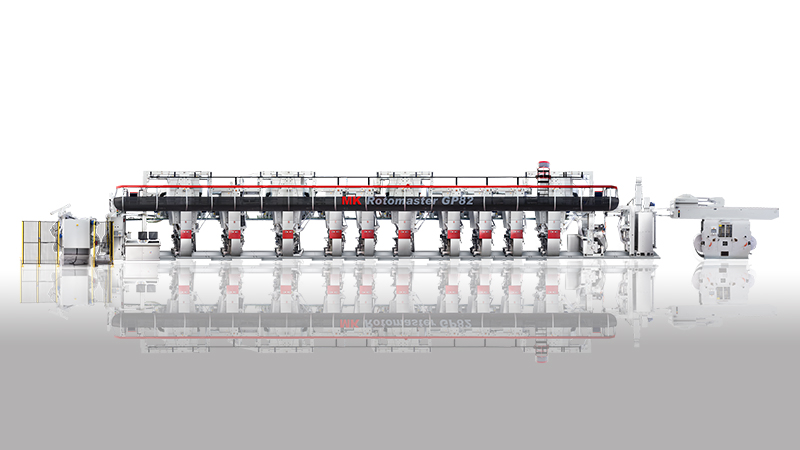

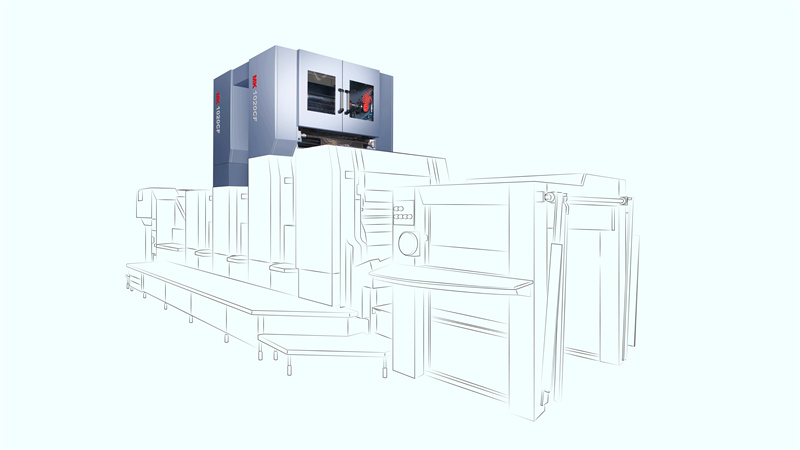

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below