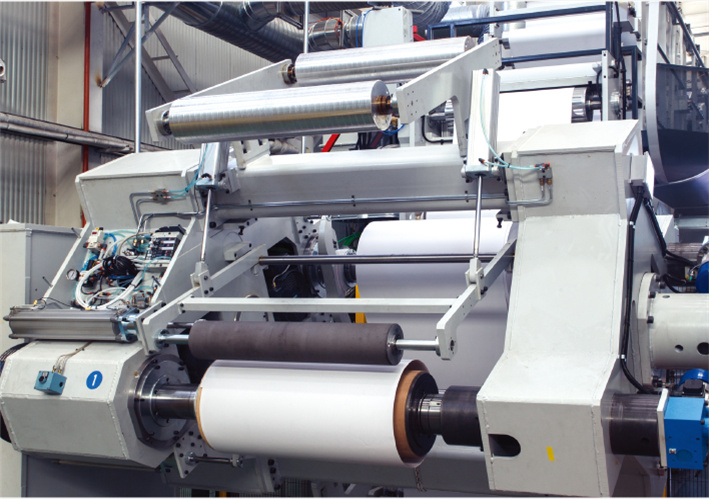

Unwinder

- Two unwinding stations with the motorized reel braking

- "Zero speed" non-stop auto web splicing

- Butt-to-butt splicing with pneumatic expandable shaft

- Splice web width from 400-850mm, available for various products

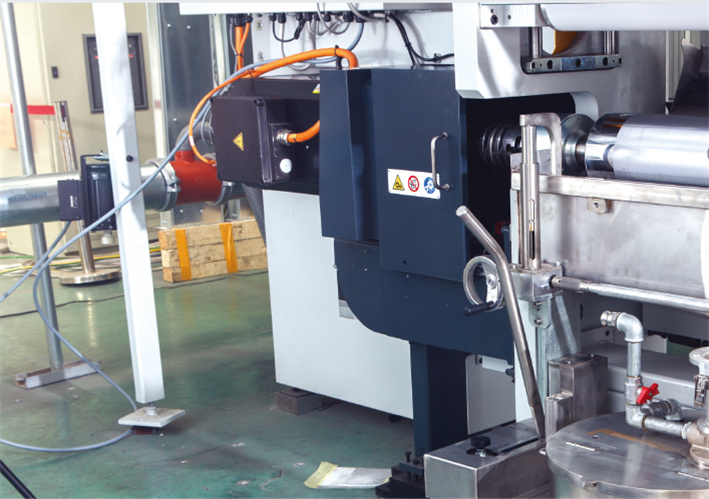

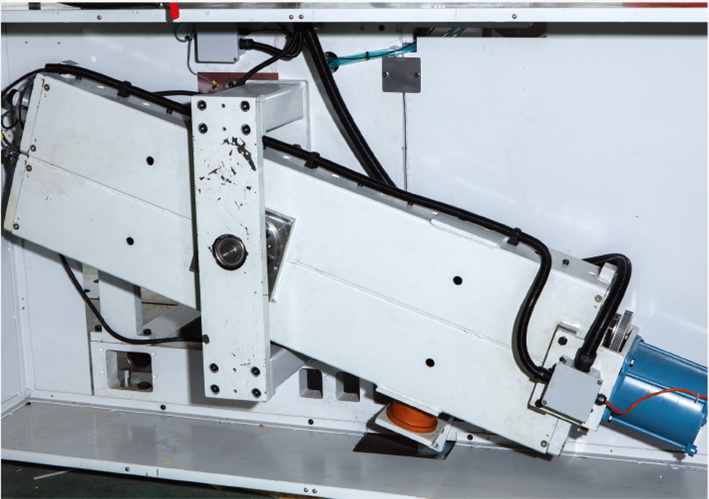

Doctor Blade

- Sliding on ball-bushings applied to eliminate the stick-slip problem

- Independently adjustable in height, parallelism and angle

- Doctor blade can tilt backwards to facilitate replacement

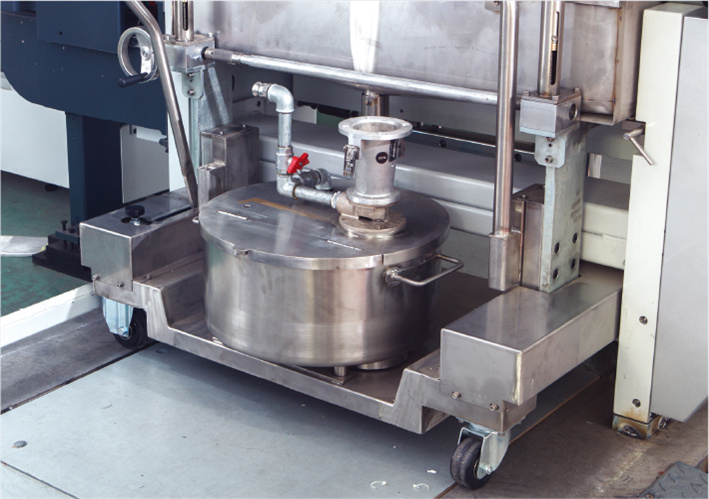

Ink Trolley

- Overall Stainless steel

- Immersion type inking system with gathering pan and level pan

- adjust height by handwheel

- 30-liter ink tank capacity

- Demountable electrical ink pump

A.C Motors with Electronic Line-shaft

- Independent drive, stable printing and accurate register

- Minimize waste for start-up and transient conditions

- Motor-driven lateral auto-adjustable stroke ±10mm

Rewinder

- Reel fixing with expandable shaft

- Independent drive for rewinding bracket

- Worm type central rotary reducer with reel core locking

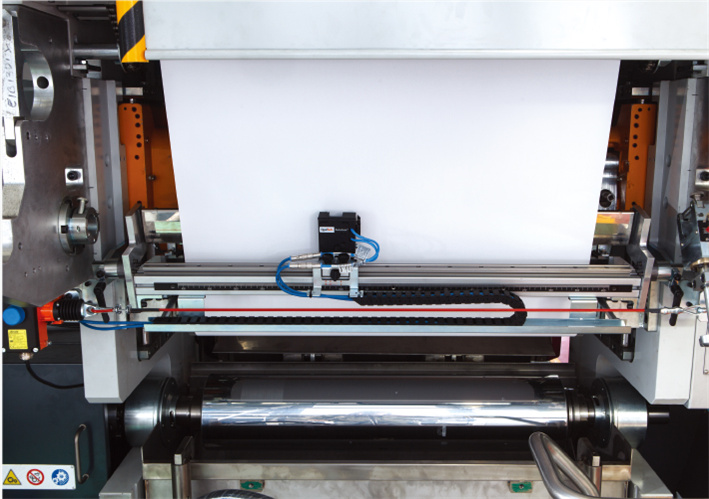

Register Device

- Automated sidelay register control system

- Special screened cable and remote control panel

- High-speed register with less waste.

- Register accuracy ± 0.1mm

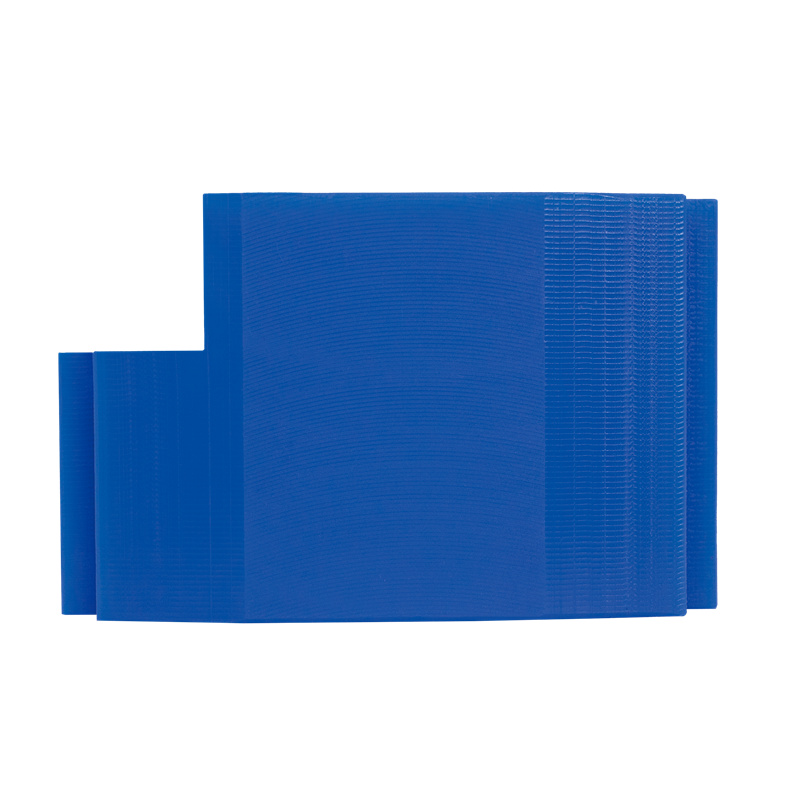

Dancing Roller

- Adjust Web tension by high precision motor

- Rapid response and quick adjusting

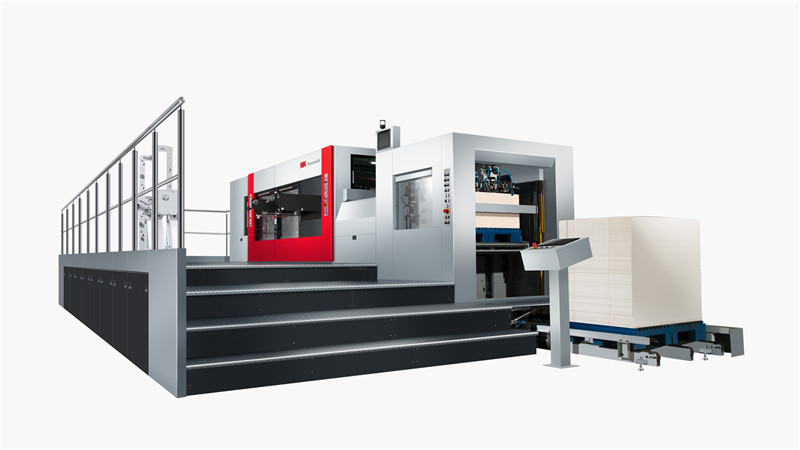

| Substrate | 80-300g/m2 |

| web widths | 500-820mm |

| Standard printing cylinder repeat range | 450-920mm |

| Max.reel outer diameter -Unwinder | 1800mm |

| Max. reel outer diameter -Rewinder | 1800mm |

| Reel core inner diameter | 6"(152.4mm) |

| Max. mechanical speed | 350m/min |

| Register accuracy | ≤±0.10mm |

| Web tension range | 10-100 daN |

| Ink tank capacity | 30L |

| Motor rated power -Printing unit | 13KW |

| Motor rated power -Unwinder | 34KW |

| Motor rated power -Rewinder | 28KW |

| Air Supply | Pressure Min.6bar,flow rate 20m³/h |

| Machine Total weight | ≈85T |

| Reel core inner diameter | 3"(76.2mm)/12"(304, 8mm) |

| Max. sheeting speed | 24,000 sheets/hour |

| Cutting tolerance | ≤±0. 08mm |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

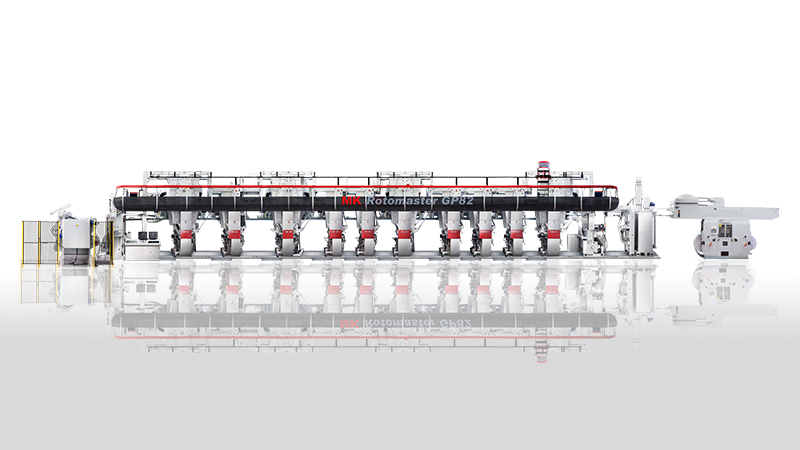

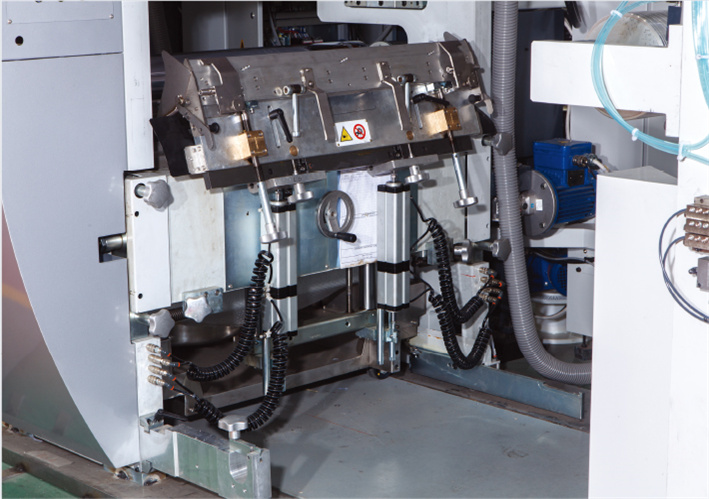

High-Speed Gravure Printing Machine

Throughout the use of a central control system, including PLC control, touch screen interface, technical operators can easily and accurately monitor the required printing quality.

This high speed rotogravure press can reach printing speed up to 350m/min. For clients who have requirement for frequent mass production, this high speed rotogravure press can be your perfect choice.

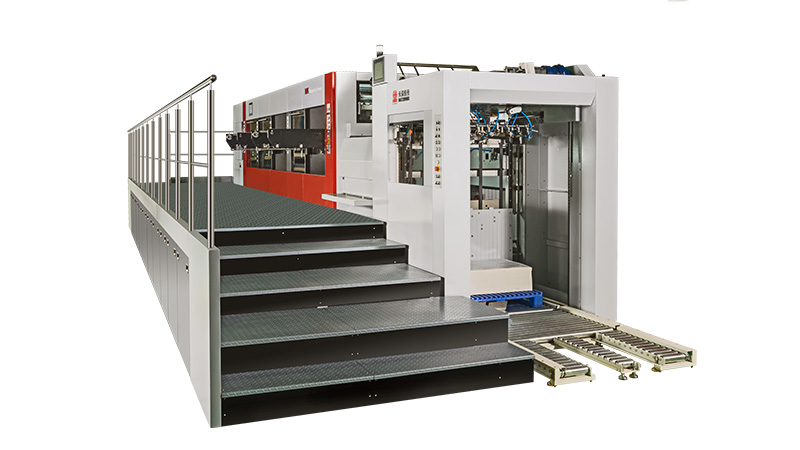

Gravure printing presses for market applications

Packaging Industry

Flexible packaging: e.g. food bags, beverage packaging, retail shopping bags, etc. Gravure printing's excellent performance on flexible materials makes it the first choice in the flexible packaging industry.

High-end packaging: Cosmetics and luxury goods packaging often use gravure printing to present a high-quality brand image.

Publication Printing

Gravure printing has a place in high-quality publications such as high-end magazines, art albums and stamps. These products require a high level of detail and color, which gravure presses meet perfectly.

Decorative industry

Decorative films: Printing of film materials for furniture, flooring and wall decoration.

Textile printing: intricate patterns and multi-color prints on textiles are widely printed using gravure printing technology.

Label and Ticket Printing

The market for tickets and lottery tickets with high security requirements, as well as highly detailed labels, also makes frequent use of gravure presses.

MK high-efficiency gravure printing presses are designed for high volume production, if you would like more information, please feel free to contact us!

+

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below