MK Box Gluing Machine Applications

1.Packaging of Consumer Goods

Used for sealing boxes containing food, beverages, cosmetics, electronics, or household products.

2. E-Commerce and Retail

Commonly used for packaging products in online retail or logistics companies

3. Food Packaging

Box gluing machines are frequently used in the food industry for packaging snack items, bakery goods, or any consumer products that require secure box closure without the need for staples or other fasteners.

4. Pharmaceutical Packaging

Ensures that pharmaceutical products are packaged securely, maintaining hygiene and ensuring the safety of contents inside the box.

5. Electronics and Hardware Packaging

Used to assemble boxes that will hold electronic devices, tools, or hardware parts

6. Cosmetic Packaging

Ideal for sealing boxes that contain cosmetic items such as lotions, perfumes, and makeup products.

7. Customized and Specialty Boxes

For businesses that require customized packaging or special shapes for their products, box gluing machines can be adapted to apply glue to specific areas or parts of the box, such as for reinforced corners or special folds.

MK box gluers are highly efficient and can apply glue quickly and accurately, saving time in large-scale production. They provide consistent bonding and reduce errors or sealing failures. They can be integrated into fully automatic packaging lines, minimizing manual work, reducing labor costs and speeding up the production process.

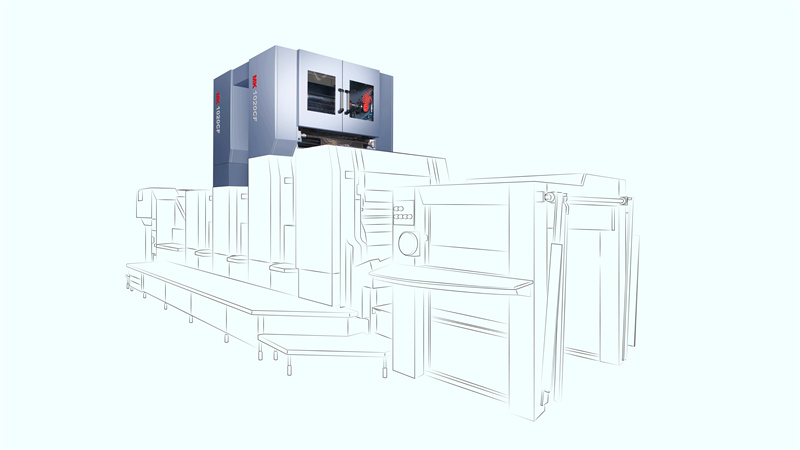

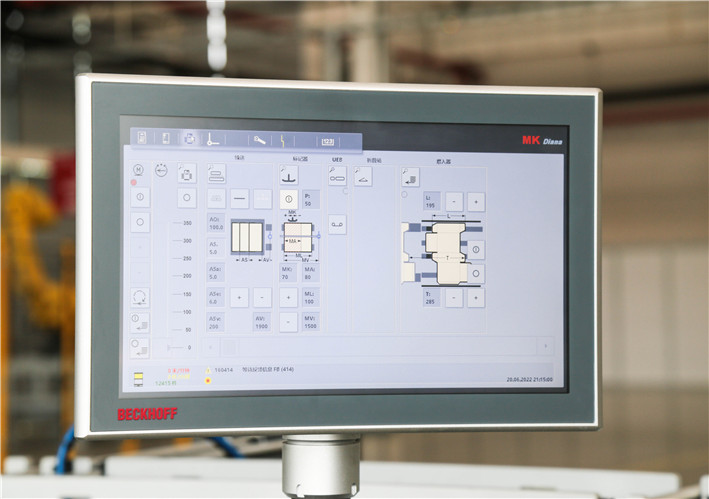

Machine Interface and Automations

- Touch-screen for machine operations

- Easy, intuitive handling of machine interface with self-explanatory navigation menu

- SmartSet: positioning of all carriers can be stored for repeat jobs (optional)

- DigiSet: automatic first set-up calculation for the positions of all carriers (optional)

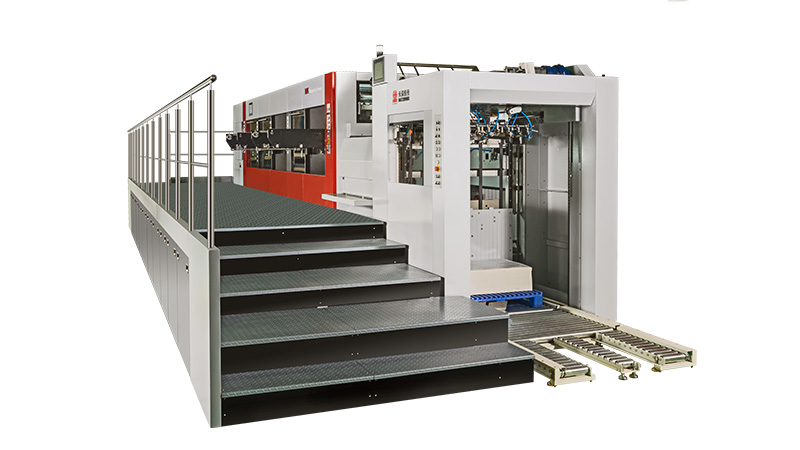

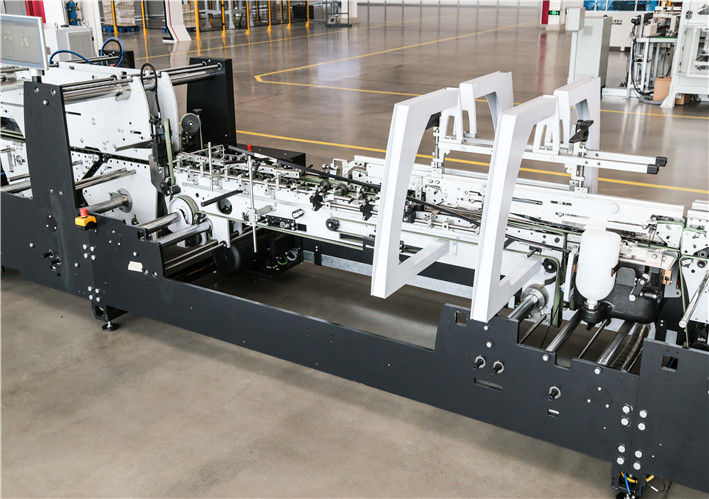

Compression Section For the formats 85 and 115 cm

- 600 mm wide compressing belt

- 2,4 m pressing section

- Softrubber belt for precise pressure balance

- Optional Start/Stop function

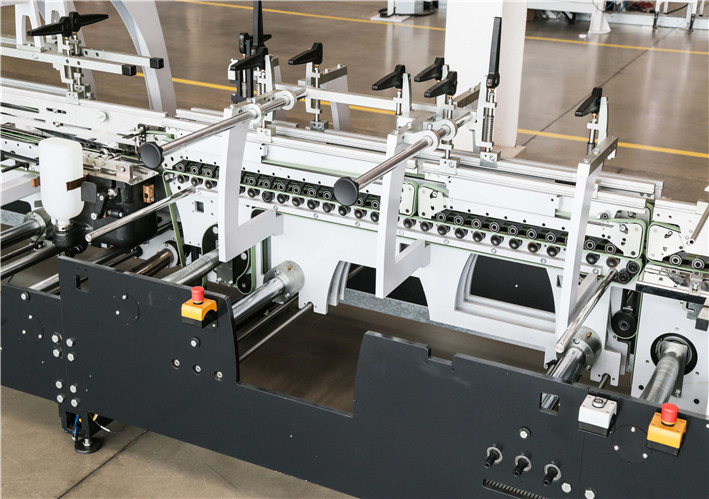

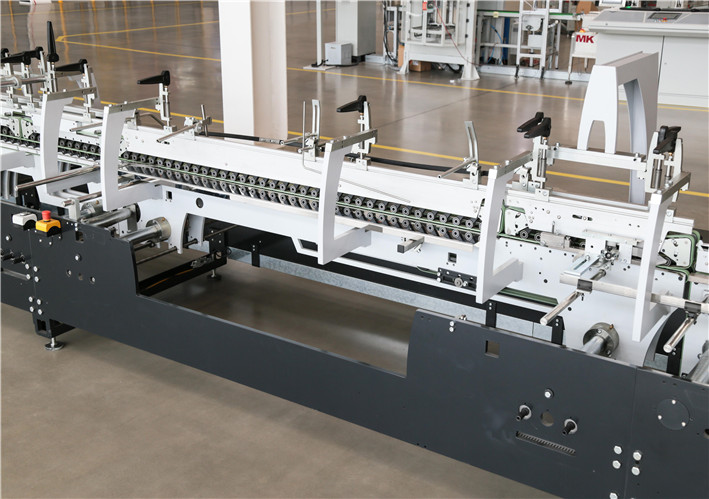

Transfer Section

- Two upper and lower carriers

- Manual adjusting of upper carriers, motorized adjusting of lower carriers

- Inline ejector optional or easy retrofitting

- Touch-screen control panel for comfortable machine operation

Folding Station

- Telescopic upper right and left roller bar

- Left before right folding and right before left folding as standard

- Central carriers as option or easy retrofitting

- Upper roller bar tiltable, easy manual assembly and dissembly of lower carriers due to light -weight construction

- Belt fold down to 45 mm open carton width are possible (optional)

Lockbottom Module

- Left, middle and right transmission belt as standard configuration

- Glue flap prefolder device at DS could be installed as optional

- Reserved installation position for the second unit back folding shaft

- Lockbottom box is equipped with gluing system optionally

Prefolding Module

- Low side frame design gives perfect accessibility for the operator

- Prebreaking for crease lines 1 and 3

- Prepared for code reader

- Upper and lower central carriers (option and retrofitting)

Feeder with Blank Aligning Module

- Designed for fast set-up

- Friction belts with fast positioning carriers

- Friction belt change in less than a minute without pulling driving shafts

- Precise length and pressure adjustable feeder gates for a good control of even odd shaped boxes

- Suction feeder system (optional)

- Blank alignment as standard in the machine

- Alignment can be done to the right or left side

- Alignment ruler sideways adjustable up to 50 mm

- Upper and lower central carrier, upper carrier is tiltable (option and retrofitting)

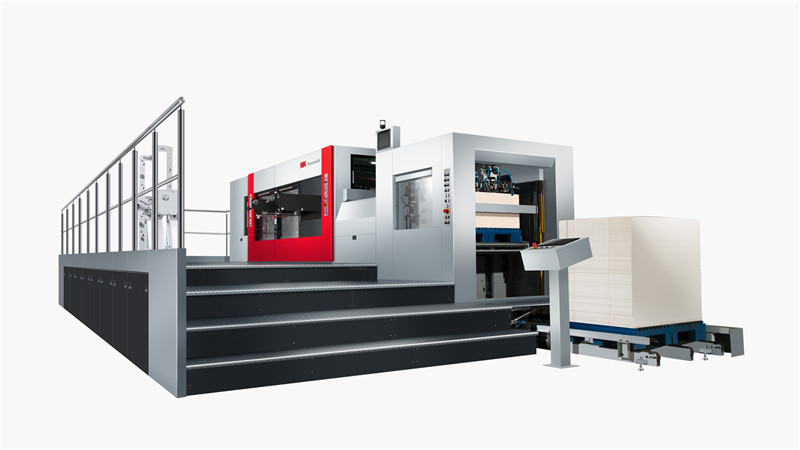

| Technical Data | |

| Max. carton width | 650mm(Diana Easy 65); 850mm(Diana Easy 85); 1150mm(Diana Easy 115) |

| Min .carton width | 75mm(Mini cartons as optional:45mm) |

| Max.carton length | 600mm |

| Sheet size | 200-600(g/m2) N/E/F micro-currugated board |

| Sheet size corresponds as follows | |

| Max.working speed | 350m/min |

| Full load power | 40KVA |

| Dimensions | Length:standard configuration is 15.5 m |

| (Diana Easy 65/85/115) | Width:2.36m/2.56m/2.86m Height:1.9 m |

| Air source requirements | 6-10 bar,the maximum flow rate is 0.6m3/min |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below