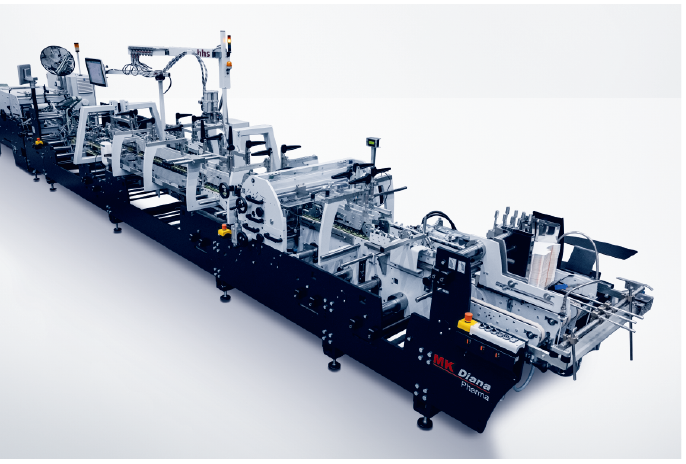

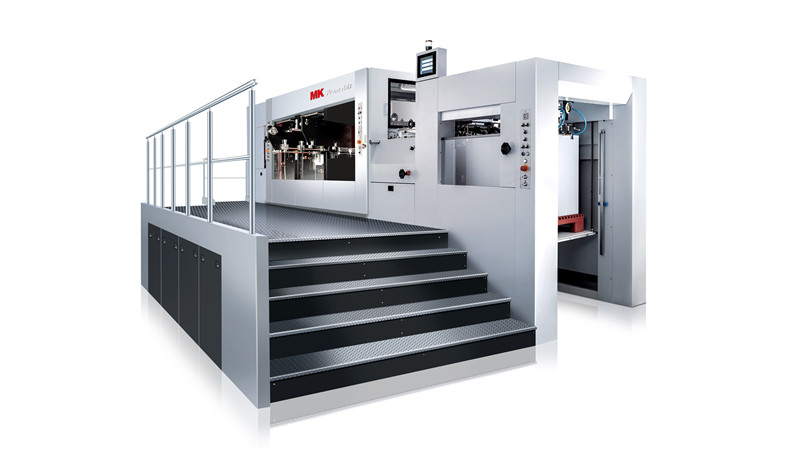

Feeder and alignment

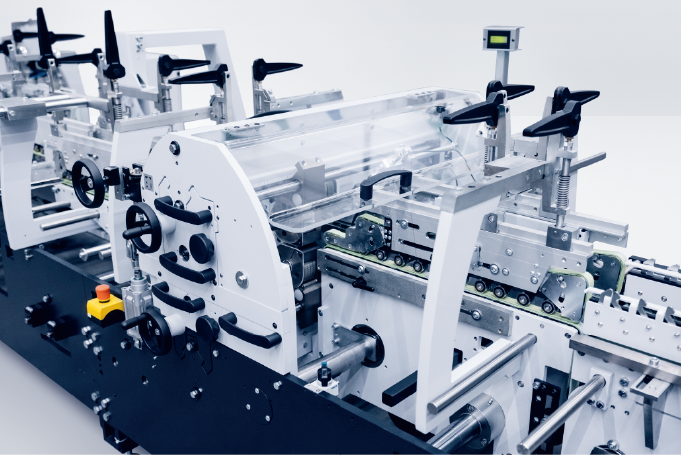

Designed for fast set-up

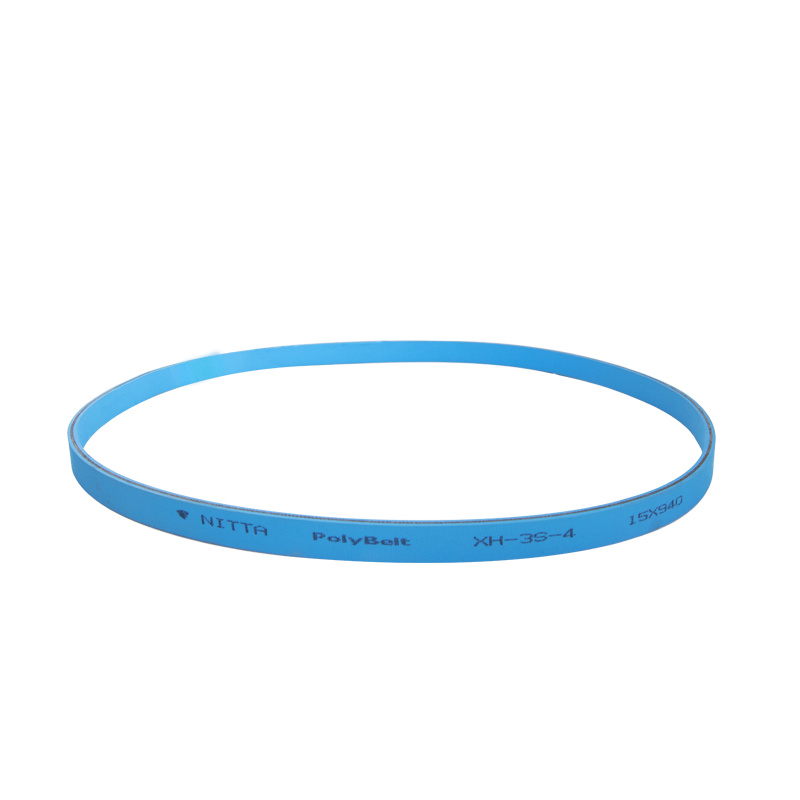

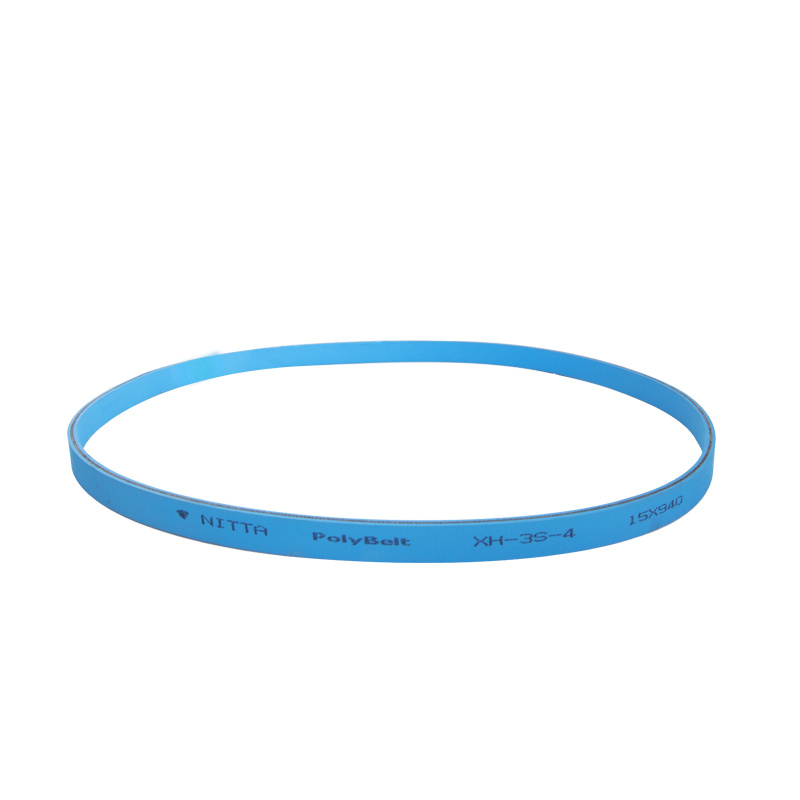

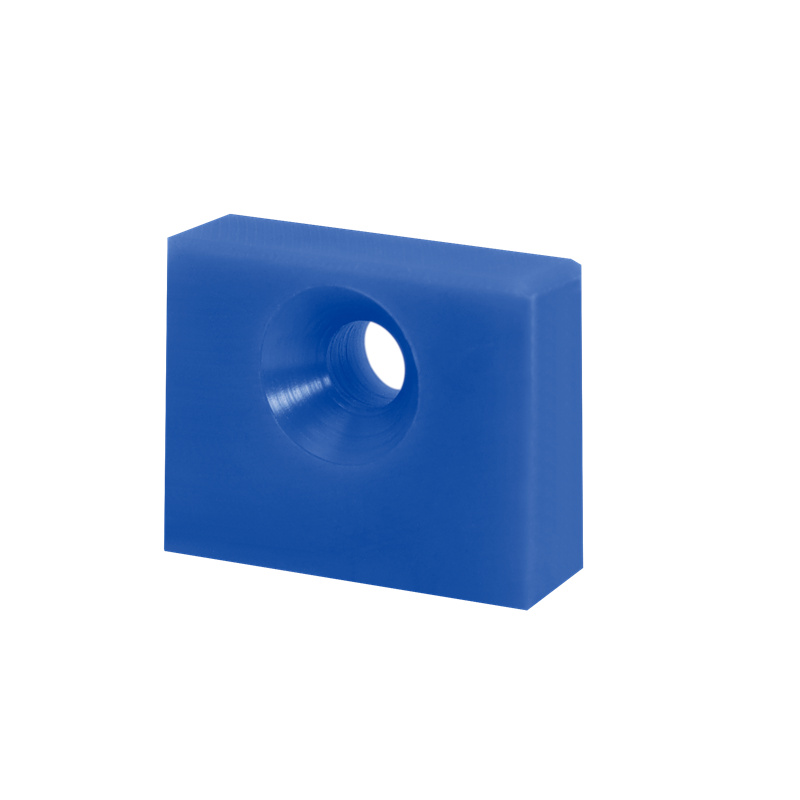

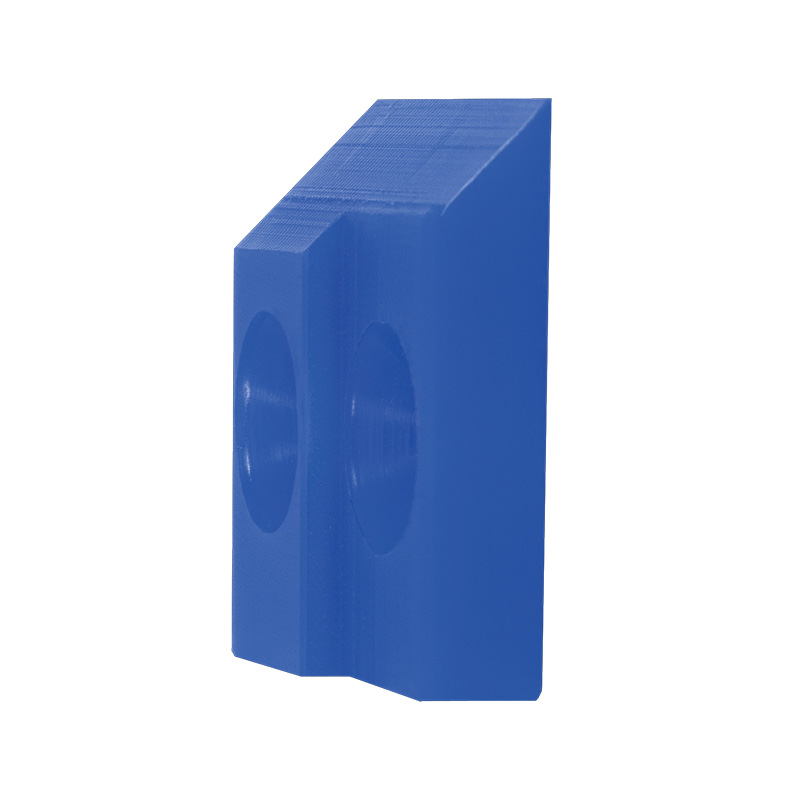

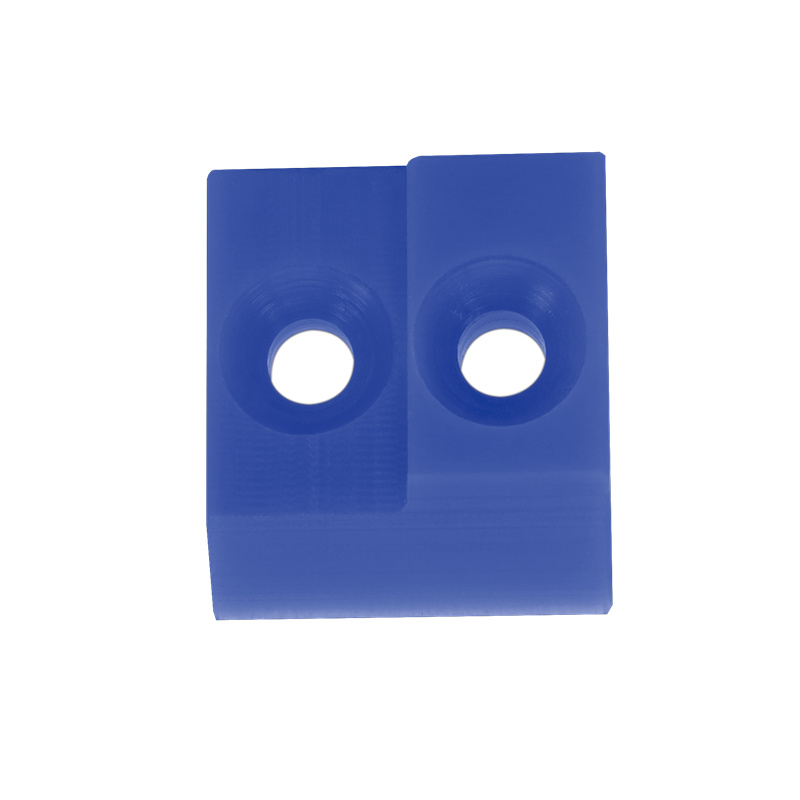

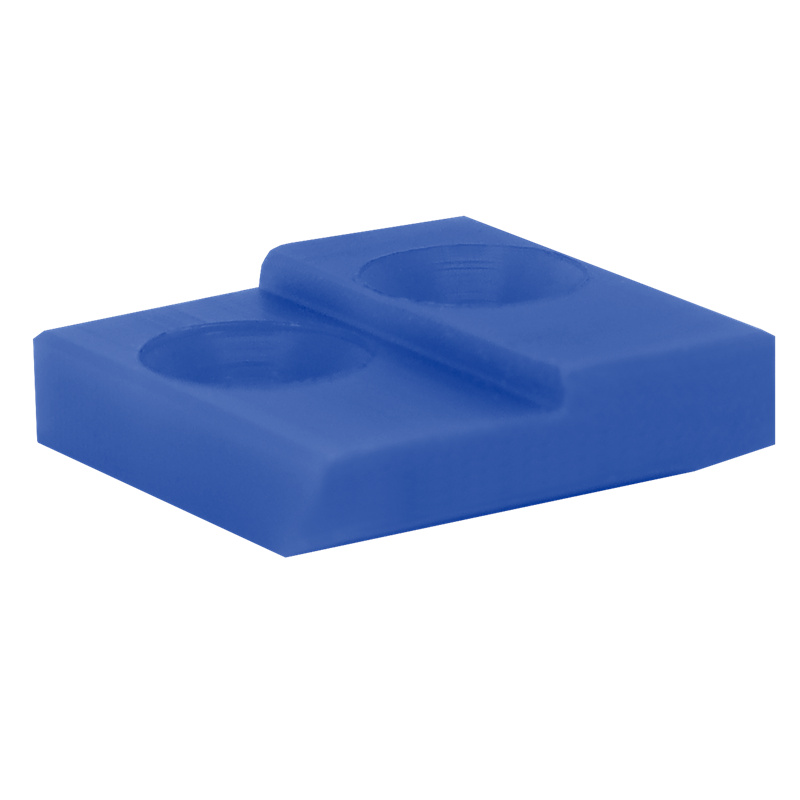

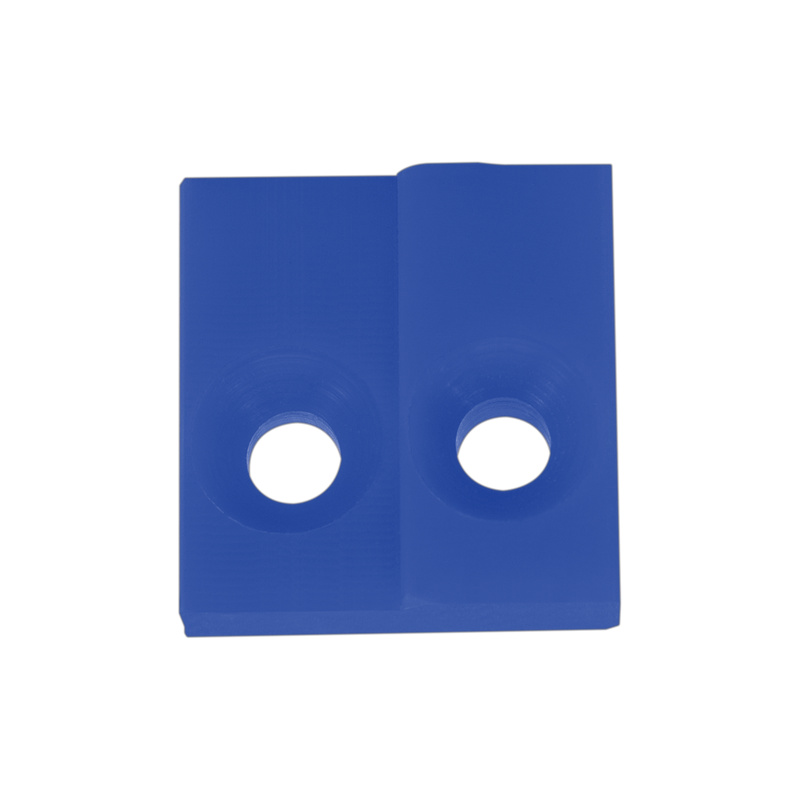

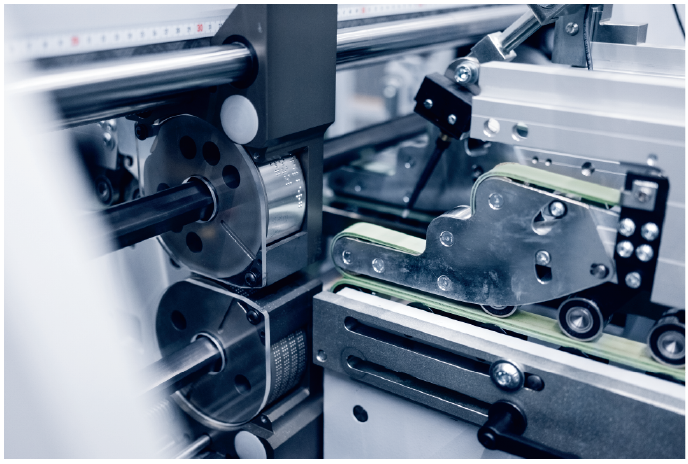

Folding carton gluing machine friction belts with fast positioning carriers

Friction belt change in less than a minute without pulling driving shafts

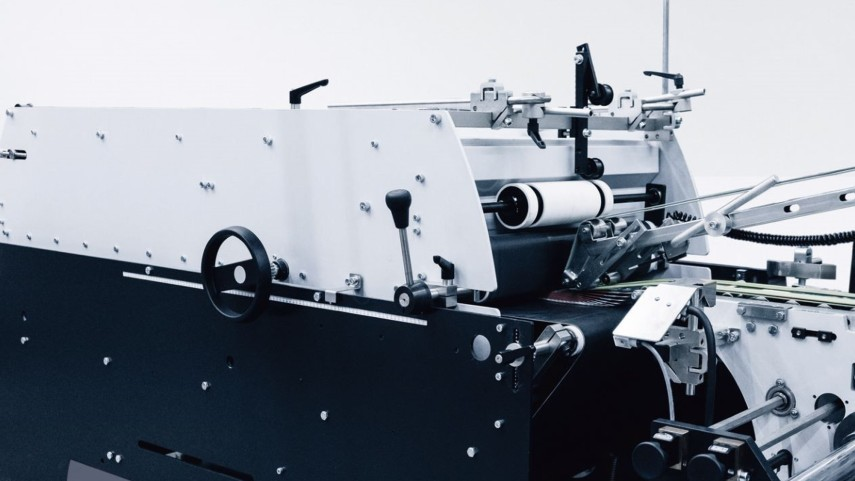

Precise length and pressure adjustable feeder gates for a good control of even odd shaped boxes

Included as standard:

Electronically controlled with vibrator

Separating air for carton blanks

Suction feeder with two suction belts

Two cleaning brushes for the feeder belts

Stacking table

Alignment ruler sideways adjustable up to 40 mm

Braille-Module

Braille embossing tools can be positioned across the entire working width

Braille applications possible on all main panels of the carton

Module length is less than 1,400 mm, regardless of the number of Braille embossing tools

High productivity

Reliable carton transport at the time of embossing

System-inherent quality control of embossing

Optimum operability and good accessibility

Proven safety concept with the GS mark

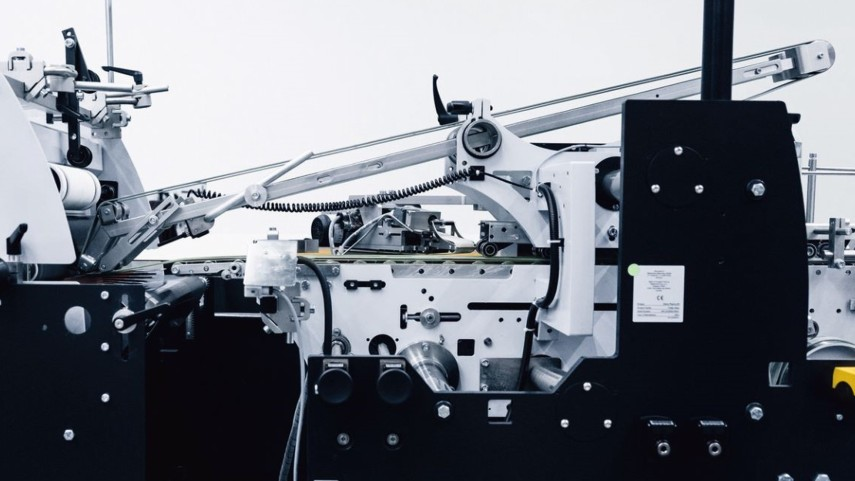

Prefolding module

Folding carton gluing machine low side frame design gives perfect accessibility for the operator

Prebreaking for crease lines 1 and 3

Prepared for code reader

Lock bottom attachment (option)

Folding station

Shiftable upper right and left roller bar

Left before right

Central carriers as option: upper and lower roller bars can be easily installed and removed due to the lightweight design

Belt fold down to 45 mm open carton width are possible (option)

Machine interface and automations

Touchscreen for machine operations

Easy, intuitive handling of machine interface with self-explanatory navigation menu

Manu-Set function

Prepared for MK Remote Service

Transfer section

Two upper and lower carriers

Manual adjusting of upper carriers and lower carriers

Ejector with MK

Linear ejctor

Carton marking device

Compression section

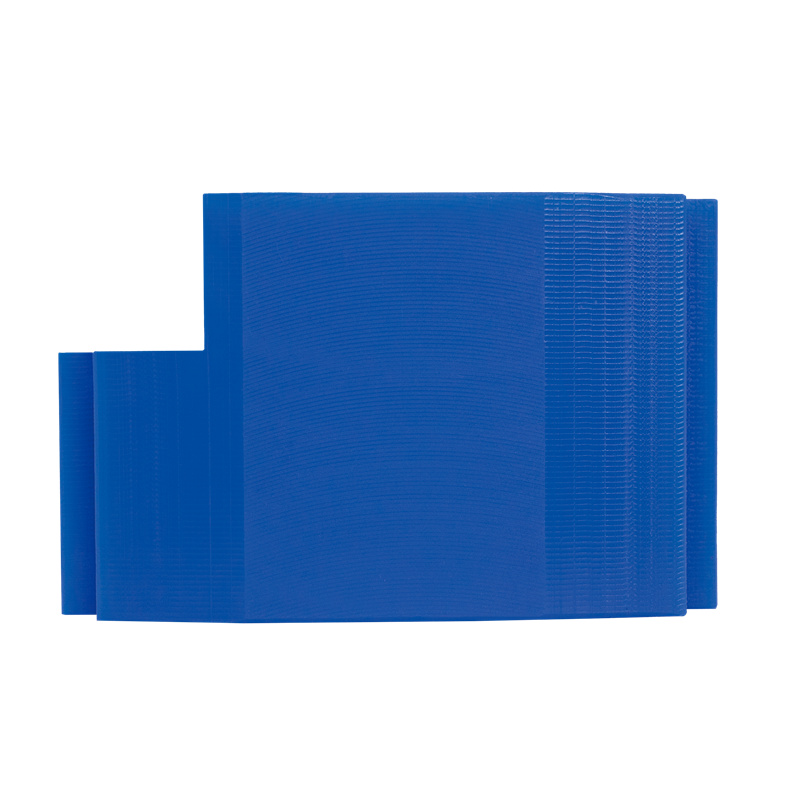

600 mm wide compressing belt

1.6 m Pressing Section

Soft rubber belt for precise pressure balance

Start/Stop function

Upgrade to longer compression and delivery possible

Processable materials - Straightline cartons

| Material (carton) | 200 - 600 g/m² |

| Material (corrugated board) | Up to F-flute (without Braille) |

| Min. carton length | 55 mm |

| Max. carton length | 400 mm |

| Min. carton width | 75 mm (45 mm optional) |

| Max. carton width | 850 mm |

Processable materials - Lockbottom cartons

| Material (carton) | 200 - 600 g/m² |

| Material (corrugated board) | Up to F-flute (without Braille) |

| Min. carton length | 80 mm |

| Max. carton length | 600 mm |

| Min. carton width | 146 mm |

| Max. carton width | 850 mm |

Performance data

| Max. speed | 250 m/min (300 m/min without active braille module) |

| Max. machine length | ca. 12 m |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

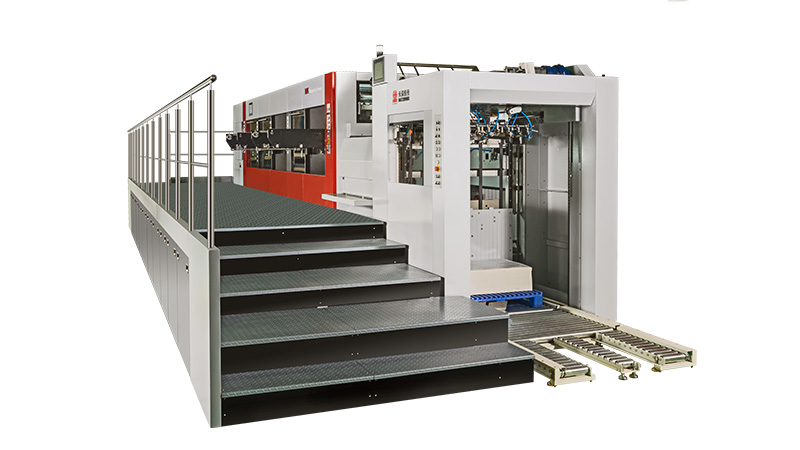

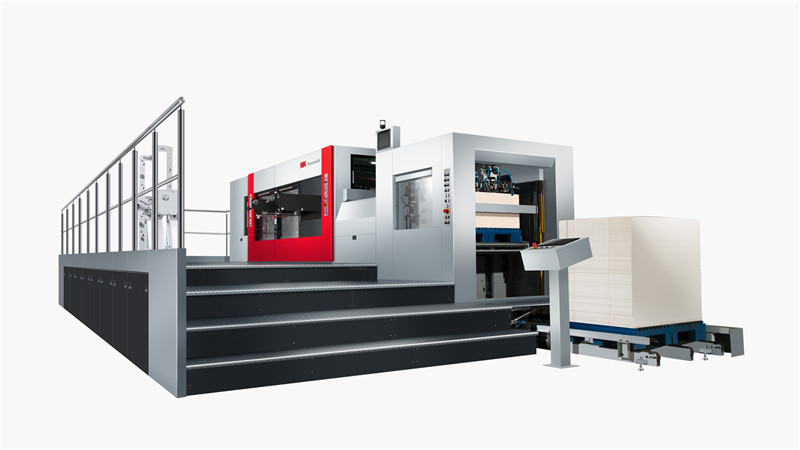

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below