Feed Station

- Adopt synchronous belt drive without maintenance

- Central adjustment of rollers and brushes

- Servo drives main/aux feeding

- Automatic lateral pile regulation

- Automatic feeder regulation

- Ultrasonic double sheet detection

- MasterSet

- Master Feeder (option, cooperate with Feeder Logistic)

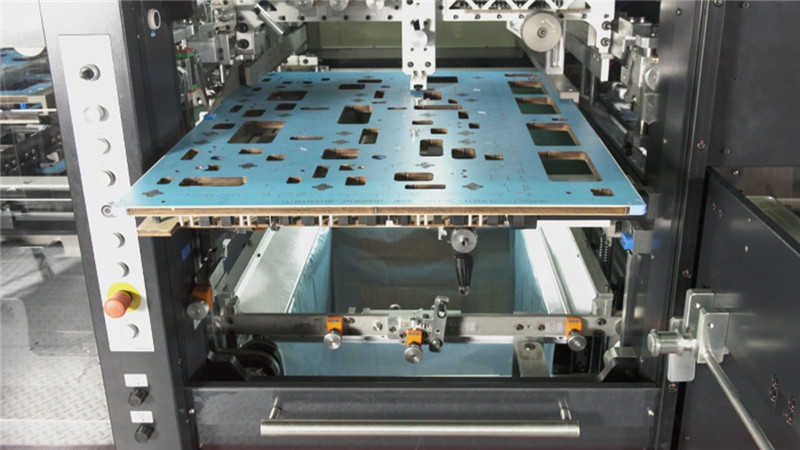

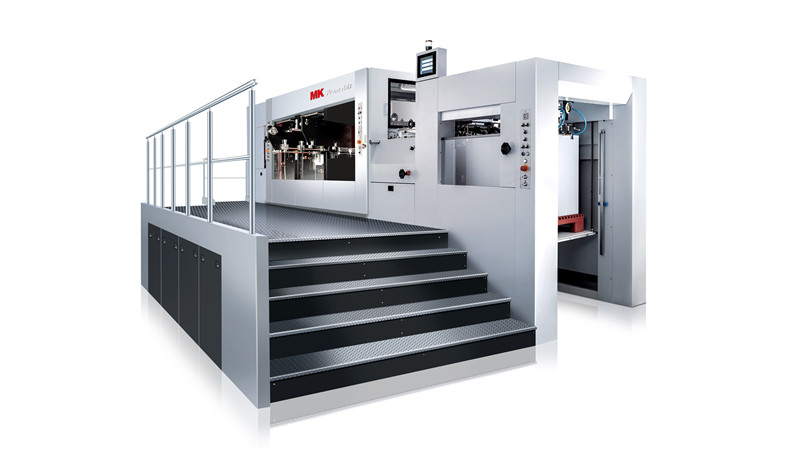

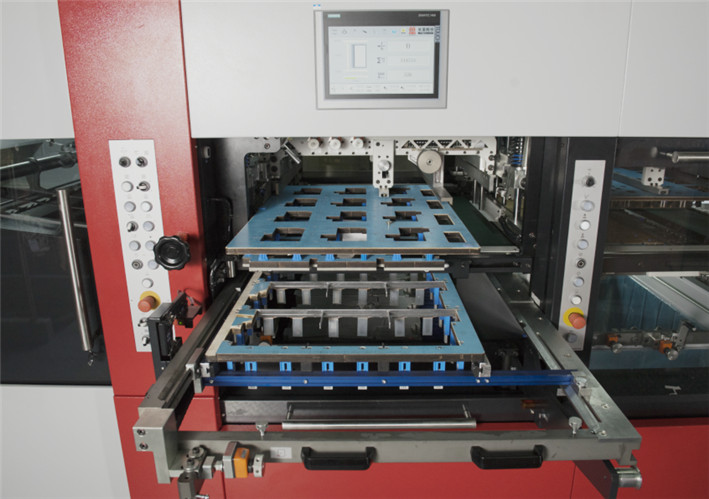

Cutting Station

- 4 heating zones at Unit I and die-cutting at Unit II

- Embossing +die-cutting in one single production process

- Register system

- Auto servo cutting pressure adjust rent

- Pneumatic locking device for die-cutting chase and cutting plate

- 2nd generation gripper bar and optimized drive curve

- Combined lower supporting plate

- Force to open the gripper when the paper not get the right position

Stripping Station

- Register system

- Integrated quick lock system for all tools (top, middle, bottom)

- Find adjustment of tools with position indicators

- Pneumatic lifting stripping upper chase

- Gripper bar positioning device

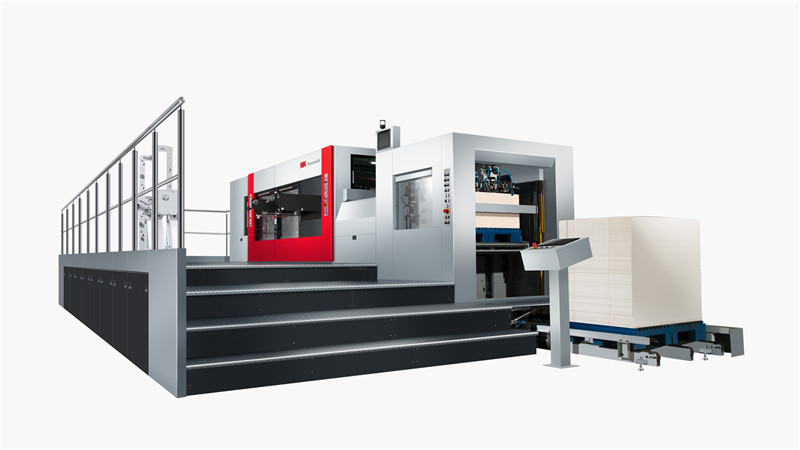

Blanking Station

- Integrated quick lock systems for all tools

- Find adjustment of tools with position indicators

- Non-stop operation

- Tie sheet inserter

- Register system

- Satisfied Euro pallet 1200 x 800mm

Test Sheet Removal

- Quality control during production

- No need to stop the production process

- Servo drive the damping brush

Control System

- Siemens control system

- Siemens color touch screen

- Friendly operation

- GS seal verifies

| Suitable material | |

| Paper(min) | 90g/m2 |

| Carton Board(max) | 2,000g/m |

| Corrugated Board(max) | 2mm |

| Performance data | |

| Sheet size(max) | 745x1,060mm |

| Cutting pressure(max) | 2.6MN/260t |

| Machine speed(max) | 7 ,000s/h |

| Pile heights(incl Pallet) | |

| Feeder pile height(max) | 1 .650mm |

| Delivery pile height(max) | 1 ,30mm |

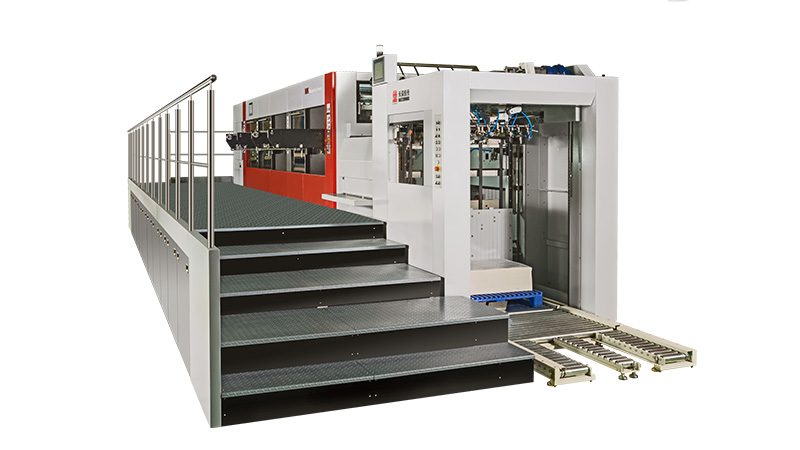

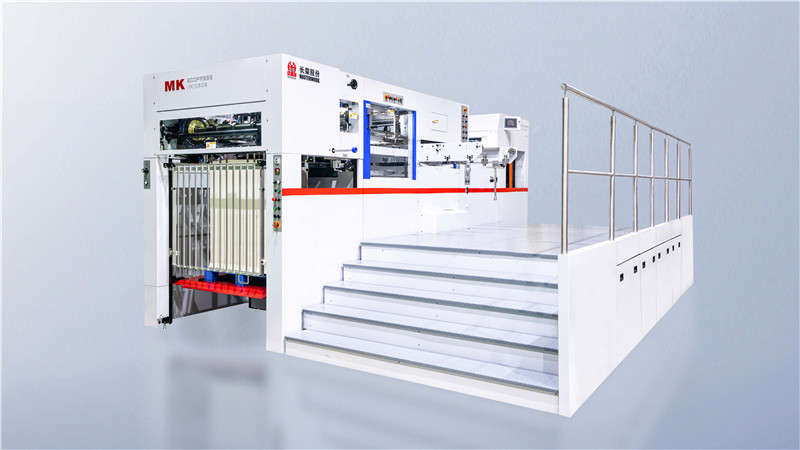

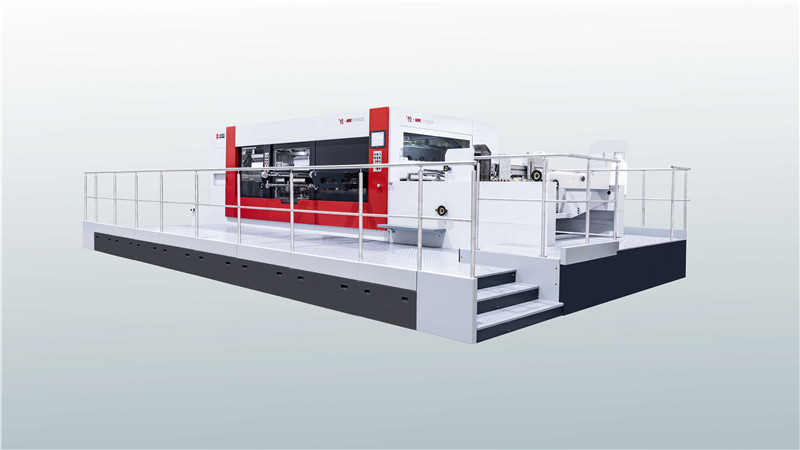

| Dimension | 12,250mm(L)x6,160mm(W)X2,760mm(H) |

| Power Supply | >0.55~0.7Mpa,0.8m3/min |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

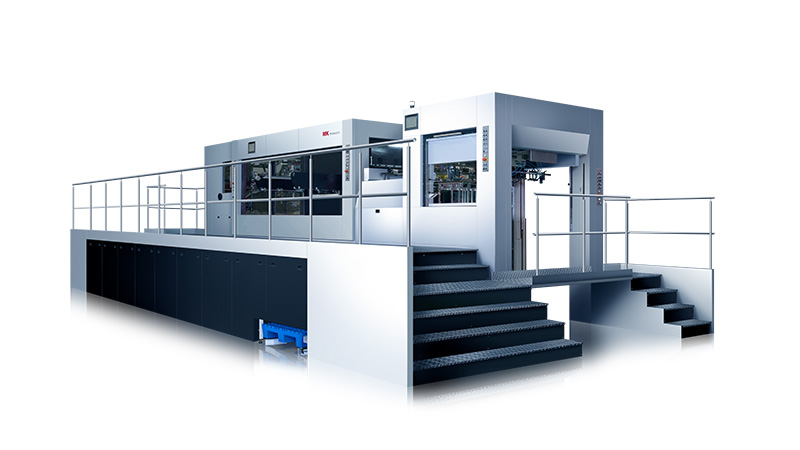

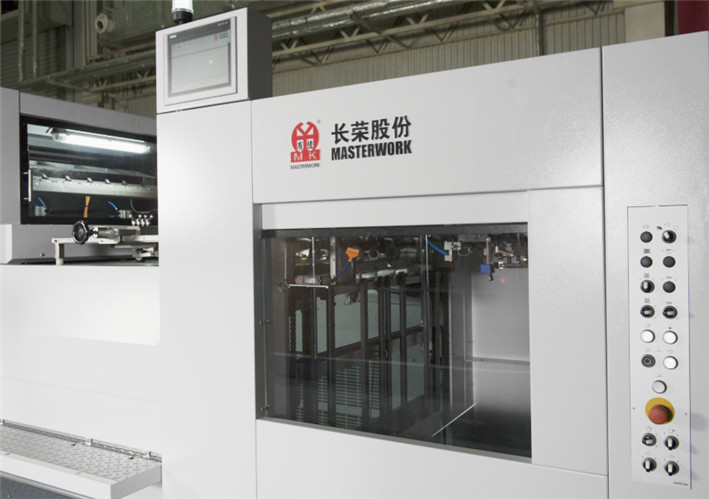

Die Cutting Equipment-Duopress Power 106CSB

Die-cutting equipment is a mechanical equipment used for die-cutting materials. This kind of equipment is usually widely used in manufacturing, printing, packaging and other fields for cutting, cutting, and die-cutting various materials, such as paper, cardboard, film, plastic, leather, fabric, etc. Die-cutting is a process in which materials are cut into specific shapes or sizes using a knife or die-cutting die.

What is industrial die cutting?

Industrial die-cutting is a cutting processing method used in mass production that uses specially designed dies or knives to cut materials into specific shapes or sizes. This processing method is often used in manufacturing, packaging, printing and other fields to produce a large number of products or parts of the same shape.

MK die-cutting machines are highly productive, designed for mass production, with computer-aided design and production, easy to operate and precise quality control. If you need more information or would like to know which of MK's machines could be just right for your needs, please feel free to contact us and have a chat with one of our experts!

How does the die cutting system work?

A die-cutting system is an automated system for precise cutting of materials into specific shapes or sizes using specially designed dies or knives. The following is the working principle of a general die-cutting system:

●Design stage: In the initial stage of die-cutting system work, users need to design the cutting graphics or templates of the product. This can be done through computer-aided design (CAD) software. In the design, the user determines the shape, size, quantity and other parameters of the cutting.

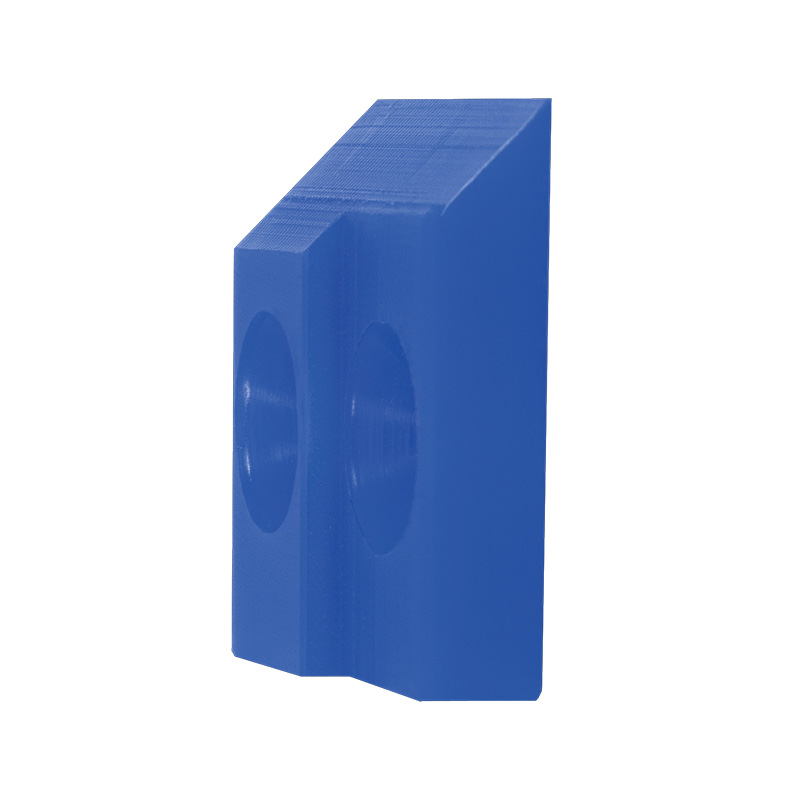

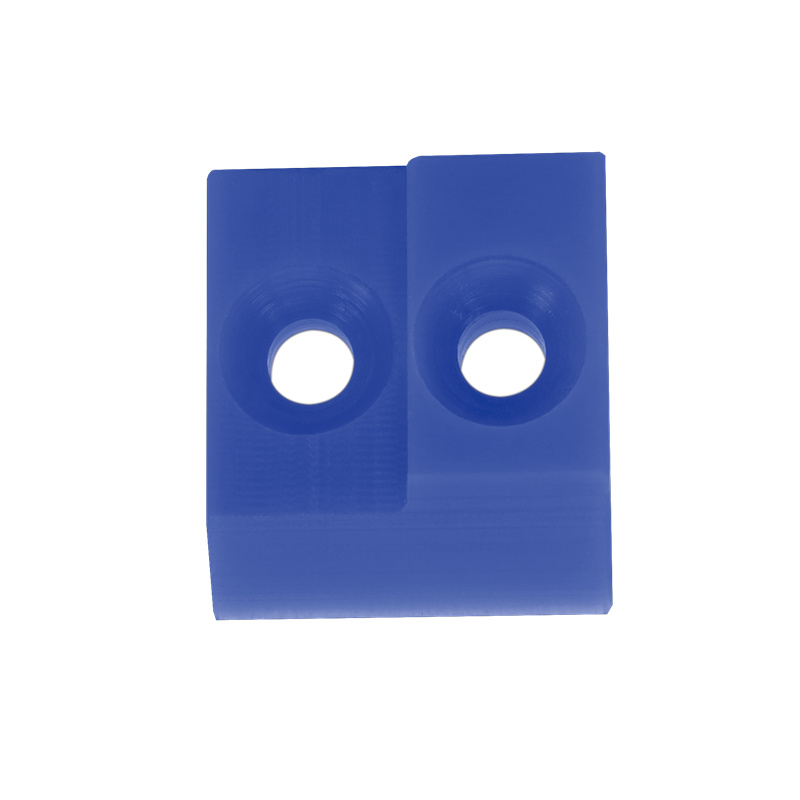

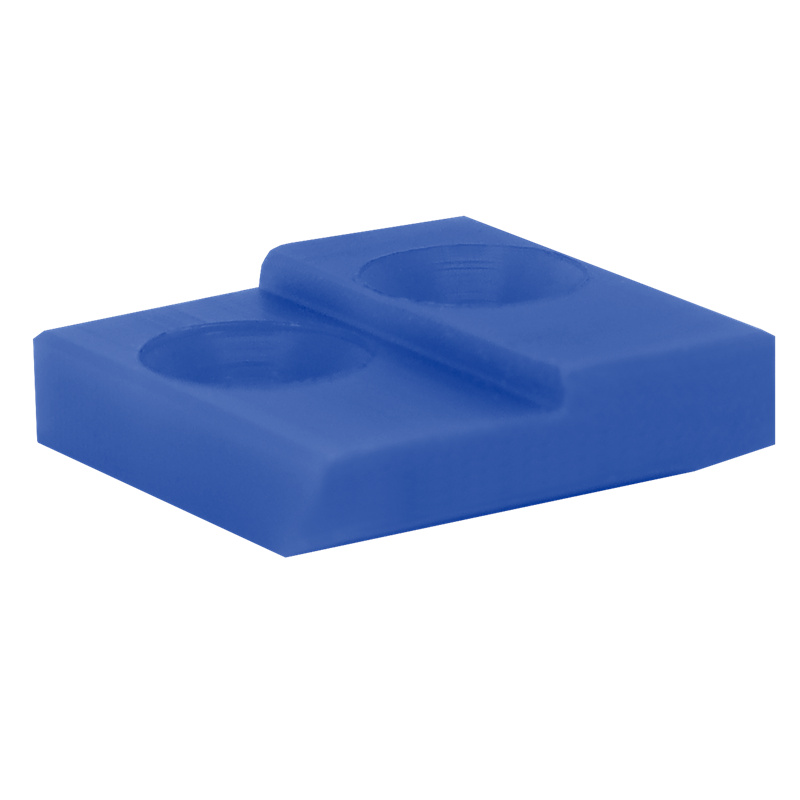

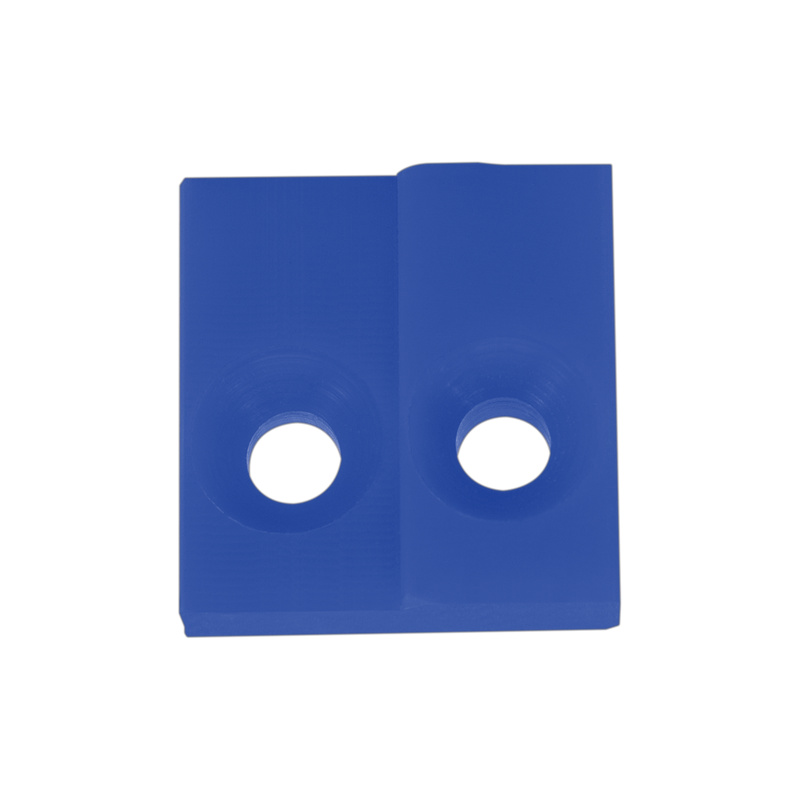

●Making knife molds: According to the designed cutting pattern, the manufacturer will make the corresponding knife molds or knives. The design of the die depends on the shape to be cut and the characteristics of the material. Dies are usually made of metal or other wear-resistant materials.

●Setting up the die-cutting machine: Once the die is ready, the operator installs it on the die-cutting machine. During this process, it is necessary to ensure that the position and fixation of the die can ensure accurate cutting.

●Loading Material: After the die cutting machine is set up, the operator loads the material to be cut onto the machine. The material can be paper, cardboard, plastic, leather, etc. The selection of specific materials depends on the requirements of the product.

●Adjust parameters: The operator needs to adjust various parameters of the die-cutting machine, including cutting depth, cutting speed, pressure, etc., to ensure that the material is cut correctly without damage during the cutting process.

●Start cutting: Once all preparations are completed, the die cutting machine begins the cutting operation. The die contacts the material and completes the cutting by pressing down or rotating. Automated die-cutting machines can efficiently complete a large amount of cutting work according to predetermined graphics or templates.

●Unloading and inspection: After cutting is completed, the operator unloads the cut material and conducts quality inspection. This ensures that each product meets the designed specifications and quality standards.

+

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below