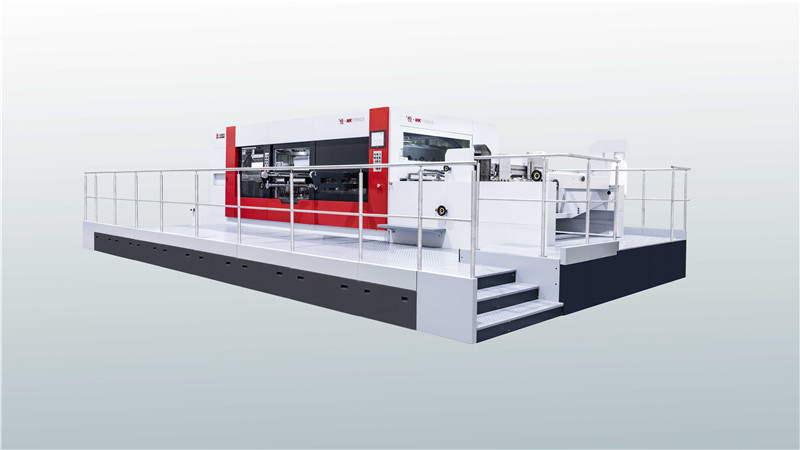

We are always committed to providing the most suitable format and equipment to our customers. Ecocut MK 170CS die cutter with stripping, “MK Corrugated Board Big Machine” , with 1700mm*1260mm Super large format. It’s fitting for all corrugated and litho-laminated board with stock thickness of 1-8.5mm. For the large format corrugated market. Ecocut MK 170CS die cutter with stripping can deliver higher running speeds, quicker change order , and matchless quality.

Ecocut MK 170CS die cutter with stripping is optional with Prefeeder 170 , which can perfectly reduce the work intensity of workers.

Exceptional precision

Extremely precise paper positioning and agile sheet transport.

Perfect die cutting, Stripping ; accurate and efficient at the same time.

Impressive production rate

Up to 6,000 sheets/hour.

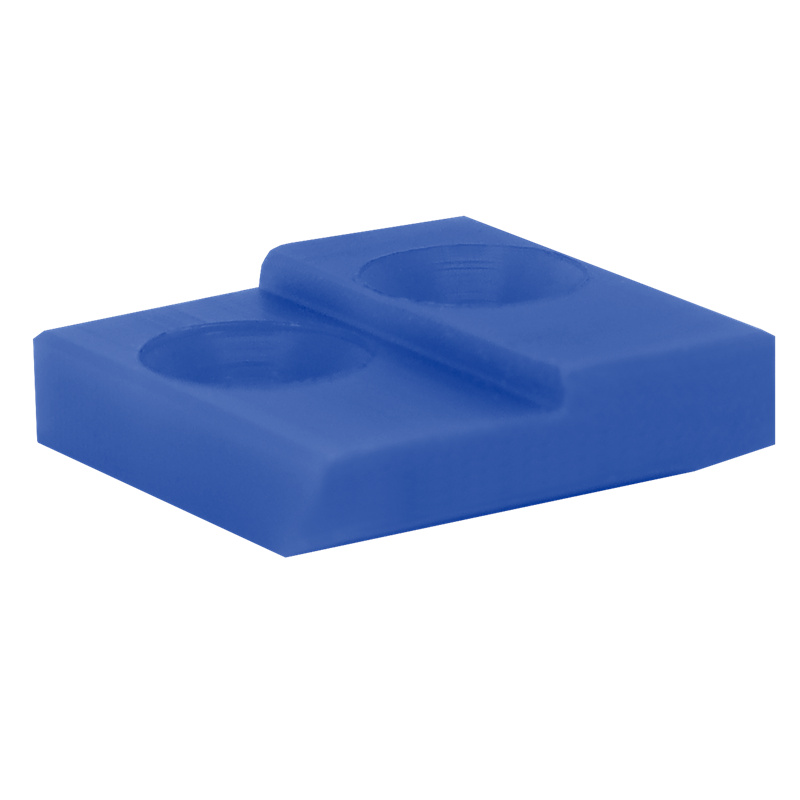

The machine equipped with the cutting plate and stripping plate with the center positioning system and quick lock system to reduce job change time and makeready time, increase productivity.

Robust, but flexible

Long-lasting, high-end quality.

It can meet the large-format die-cutting requirement of multi-blanks corrugated board and litho-laminated board.

Excellent for long and short order runs.

Infeed unit

- The new generation of front edge feeding devices combines the front edge feeding technology of high-speed printing machines and die-cutting machine feeding, resulting in high feeding accuracy and strong suction power.

- The auxiliary feeding device is more convenient for stable sheet feeding.

- The high-torque servo motor controls the sheet in place to slow down and ensure that the sheet is flat when it reaches the front lay.

- The corrugated board has a more extended lay, and a wider front lay stopper to ensure accurate positioning.

- Pneumatic side alignment device: the front holder can be adjusted electrically for height.

- Equipped with one set of side positioning lay on the left and right

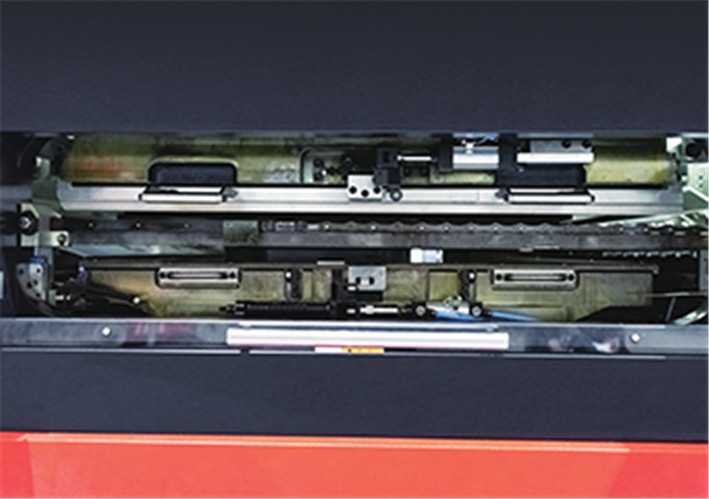

Die-cutting unit

- Pressure adjustment: max. die-cutting pressure 400T

- Empty running and sheet falling detection system

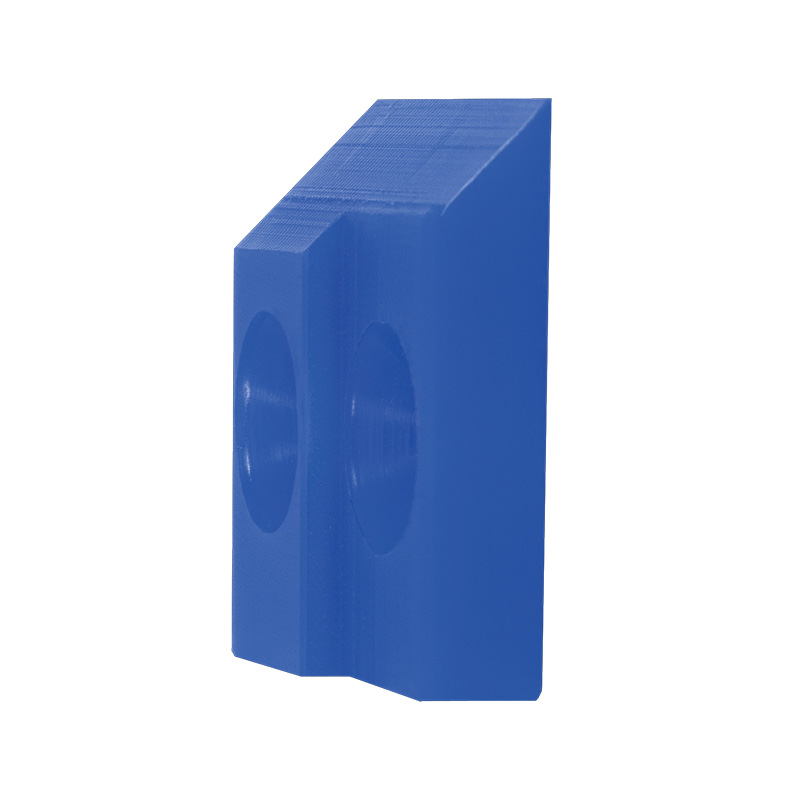

- The frame and the lower plate have pneumatic locking devices for easy handling.

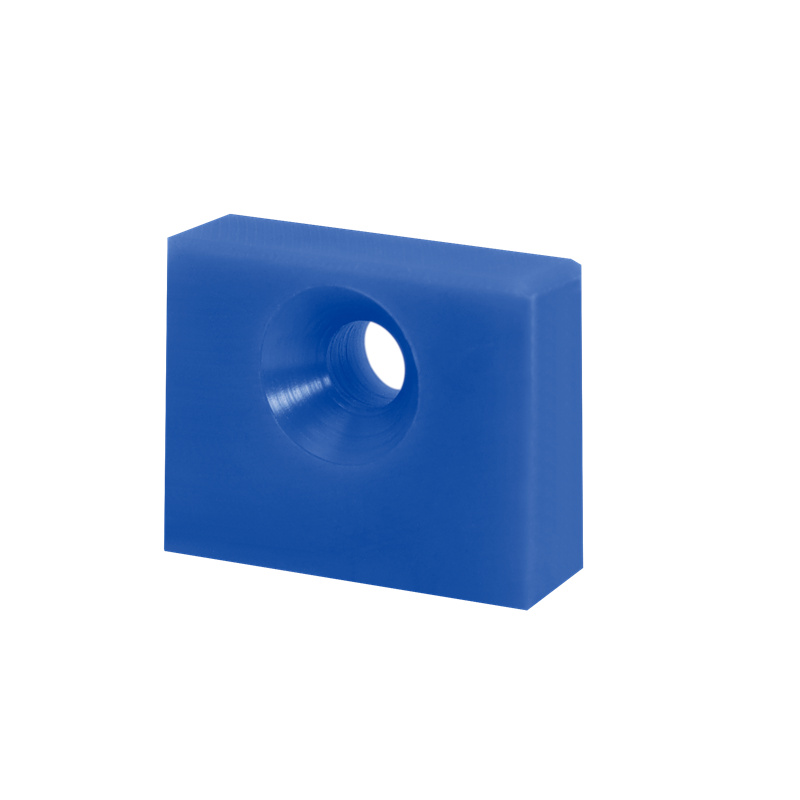

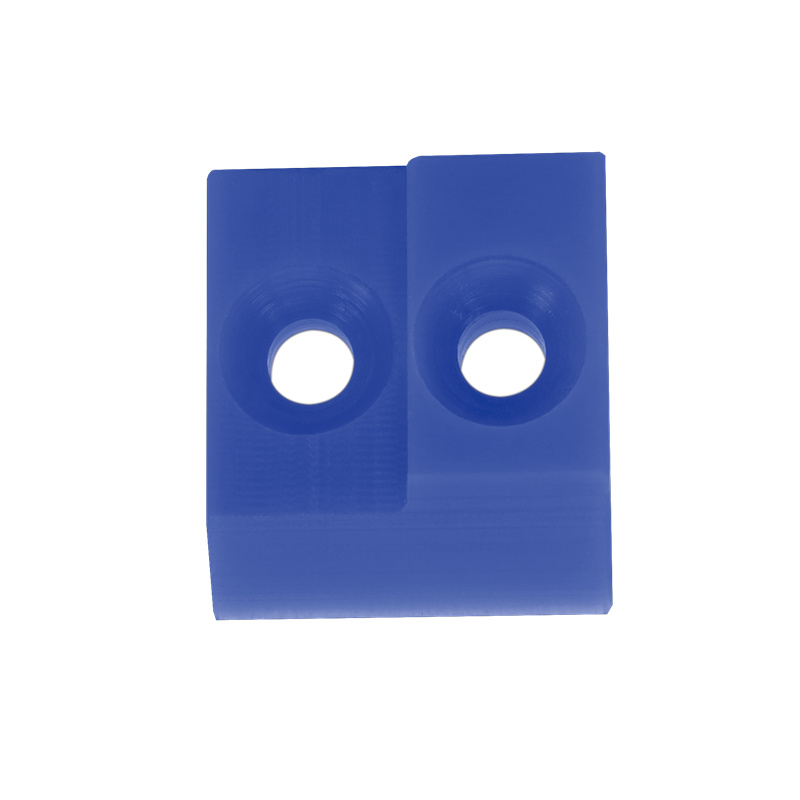

- Center positioning of the die-cutting plate

- The lower plate is equipped with a holding device to push and pull more smoothly.

Stripping unit

- The upper stripping frame lifted electrically for easy operation.

- The upper and middle stripping frames are centered positioning, making the plate change quickly.

Delivery unit

- Standard configuration of gripper edge removal device and waste edge delivery device

- Paper alignment device for front/back/side of the delivery stack

- Electric auxiliary delivery device can deliver sheets without stopping the machine.

- There are two delivery solutions to choose from: high stack delivery(automated logistic as an option) and conveyor belt delivery.

Lubrication system

- The main moving parts of the machine are lubricated by a centralized automatic lubrication

- system, which effectively reduces the maintenance time and prolongs the device’s service life.

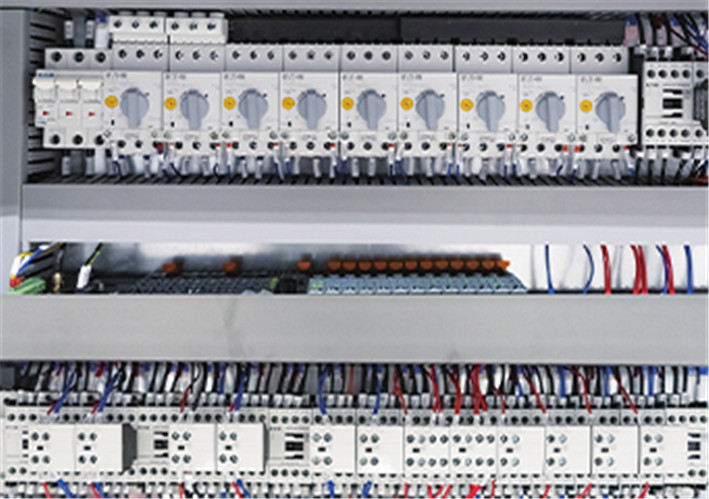

Control system

- B&R control system for the whole machine

- The electrical control components are modular in design to facilitate maintenance.

- The electrical control design of the machine meets national safety standards. In addition, it is optimized for logic control and has a remote maintenance interface.

| Max. sheet size | 1700mmX1260mm |

| Min. sheet size | 650mmX450mm |

| Max. die-cutting size | 1700mmX1245mm |

| Sheet specification | 1-8.5 mm (E,B, C,A and AB corrugated board) |

| Gripper margin | 12-18mm (when the first ctting line is standard 20mm) |

| Max. pressure | 400T |

| Max. speed | 6000s/h |

| Max. feeding pile height | 400mm (lower suction feeding) |

| Max. delivery pile height | 1450mm (incl. pallet) (high stacking delivery) 180mm (Counting stacking belt) |

*The machine speed and precision will vary according to different model types. | |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Corrugated Flatbed Die Cutting Machine

In the ever-evolving world of manufacturing, optimizing efficiency and precision is critical. If you're looking for a game-changing addition to your production line, look no further than large format corrugated flatbed die cutters. These innovative machines combine cutting-edge technology with precision engineering to provide seamless solutions for a wide variety of industries.

As a manufacturer of large-format corrugated flat-bed die-cutting machines, MK provides accurate, flexible and easy die-cutting of corrugated cardboard, while meeting your various sizes and automatic flat-cutting requirements, easy to use, high-speed production efficiency .

Flexible: non-stop feeder and non-stop delivery

Accurate: die cutting accuracy up to ± 0.15mm

Easy die-cutting: 1-8.5 mm (E, B, C, A, and AB corrugated board) is suited for a flatbed press

Corrugated Die Cutting Processing

Corrugated Die Cutting Machinery has different corrugated flated die cutting processing operations such as die cutting, slitting, edge trimming and cutting to length can all be combined into one pass to yield a high output flexible processing center.

Feature

Simple, Productive, High Volume

The Corrugated Die flatbed Cutting machine is simple to use, highly productive and is designed to increase the value and prolong the life of your machining production investment. Designed primarily for companies needing high volume production of corrugated cardboard and carton.

Corrugated flatbed die cutting machines are used in two main industries, these being the manufacture of corrugated packaging that has high printing and die-cutting requirements, and the production of in-store displays from corrugated board.

Ecocut MK 170CS Flatbed Die Cutting Machine

Our flatbed die-cutting services provide a wide range of materials conversion options, including cardboard, paperboard, and corrugated cardboard. MK's 170CS flatbed die-cutting machine is specifically designed to handle these materials, delivering efficient and precise results.

For more information on our exceptional flatbed die-cutting services from MK or to speak with one of our highly knowledgeable professionals, please feel free to Contact Us or complete our convenient online Request A Quote form.

Industries rely on the versatility of industrial flatbed die-cutting machines for high-volume production. The packaging industry, for instance, utilizes these machines to create a multitude of products such as boxes, cartons, and other packaging solutions. In the sign-making industry, flatbed die-cutting machines excel at cutting various materials, including vinyl, acrylic, and others, into customized shapes for signage and displays. The graphic arts industry benefits from the precise cutting capabilities of flatbed die-cutting machines, enabling the creation of specific shapes for applications like card making, scrapbooking, and other crafts.

The Ecocut MK 170CS is a robust hydraulic flatbed die-cutting machine, also known as a platen die-cutting machine, renowned for its exceptional performance. This state-of-the-art machine offers numerous advantages:

Accommodates large sizes of materials, enabling cutting of substantial pieces.

Handles a broad spectrum of thin and thick materials, including sheets and rolls, with remarkable ease and precision.

Optimizes material usage by efficiently cutting closely grouped shapes, minimizing wastage.

Represents a cost-effective solution compared to rotary die-cutting machines, delivering outstanding value for your investment.

Looking for a fully automatic cardboard die cutting machine? Or to find out more about the Ecocut MK 170CS die cutter with stripping, drop us a line, we look forward to hearing from you and offering you some advice!

+

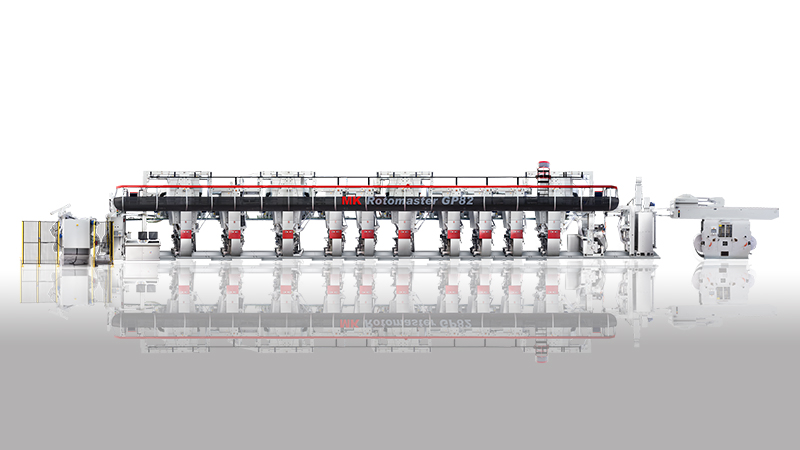

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below