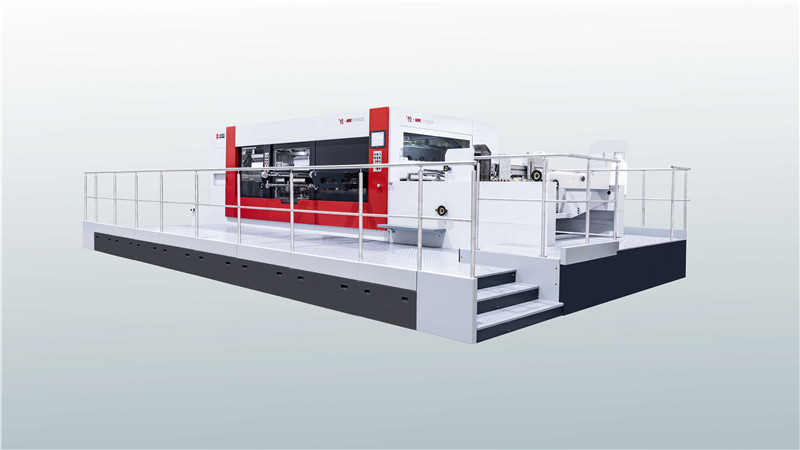

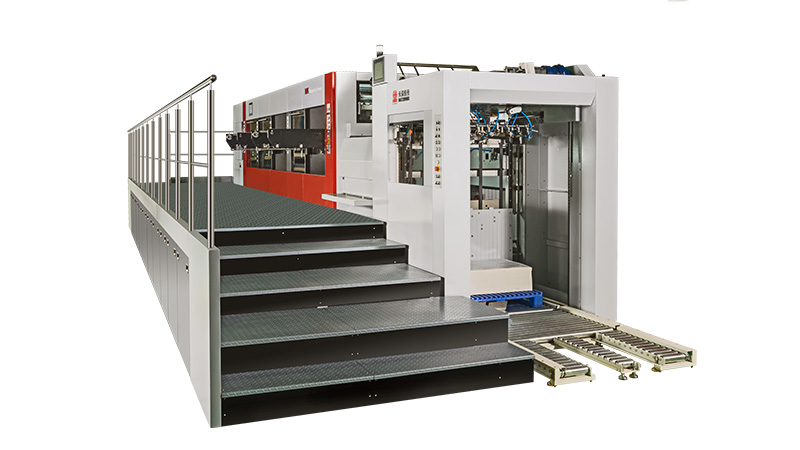

Ecocut MK 130CS is the die cutting machine with stripping developed by MK for the medium-format corrugated board market. It is applicable for corrugated board with the width of 1300x960mm and the thickness of 1-5mm. Regardless of the complexity of the product size, this machine offers great versatility, excellent reliability, and superb productivity. The highly automated and customized design concept reduces the difficulty of operation and makes the operator more comfortable, helps your company fully raise the production capacity of corrugated board to new heights.

Ecocut MK 130CS is equipped with the quick changing chase . gripper edge removal device, pile lifting device. With the smaller area, lower energy consumption and wider product suitability, Ecocut MK 130CS brings you a new world of corrugated board production.

Cardboard Die Cutter Ecocut MK 130CS Product Advantage

Exceptional precision

Smoothest sheet transport and outstandingly precise cutting precision.

Perfect stripping, waste removal and batch alignment for impeccable blanks.

Impressive production rate

Up to 6,000 sheets/hour.

Quick change chase for more uptime.

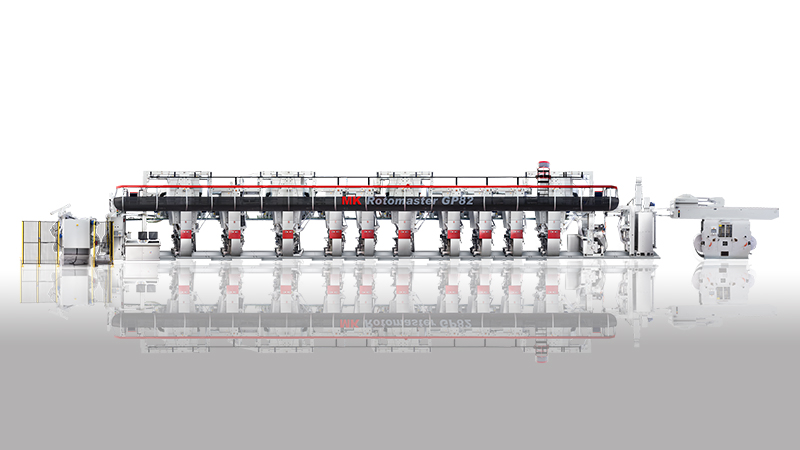

Ecocut MK 130CS is optional with fore-and-backhand combination die cutting machine to form a high performance of corrugated board production line.

Robust, but flexible

Long-lasting, high-quality construction.

Handles a large range of materials.

Ideal for long and short order runs.

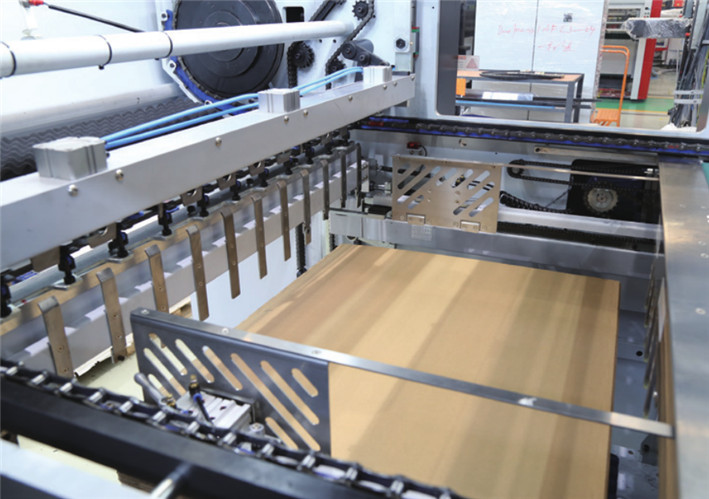

Infeed Unit

- The down side suction feeding mechanism of MK patent technology effectively avoids sheet scratches during feeding,and better solves the problem of warpage sheet conveying.

- The sheet feeding is driven by the high-torque servo motor to ensure that the sheet is flat when it reaches the front lay.

- Front lay sensor detection and double sheet detection system

- The side holder of the feeding section is adjusted by motor drive.

- Pneumatic side aligning device:The front holder can be adjusted electrically for height.

- Equipped with a set of side positioning push lay on both sides to ensure the accuracy of the side positioning

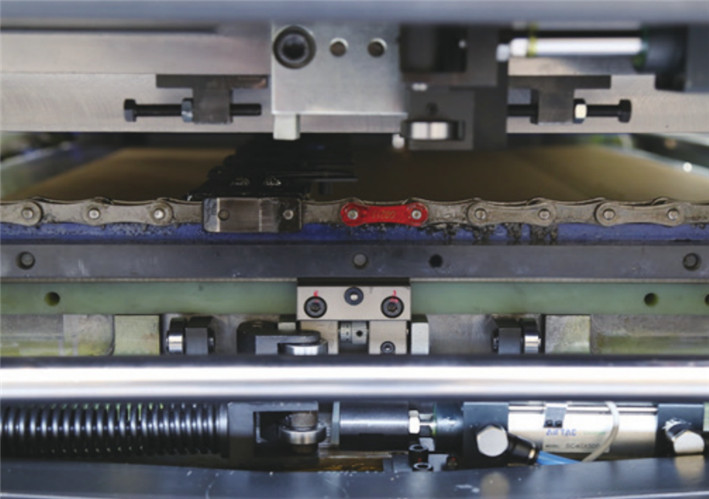

Die-Cutting Unit

- Pressure adjustment: max.die cutting pressure is 200T.

- Empty running and sheet drop detection system

- Die cutting plate central positioning

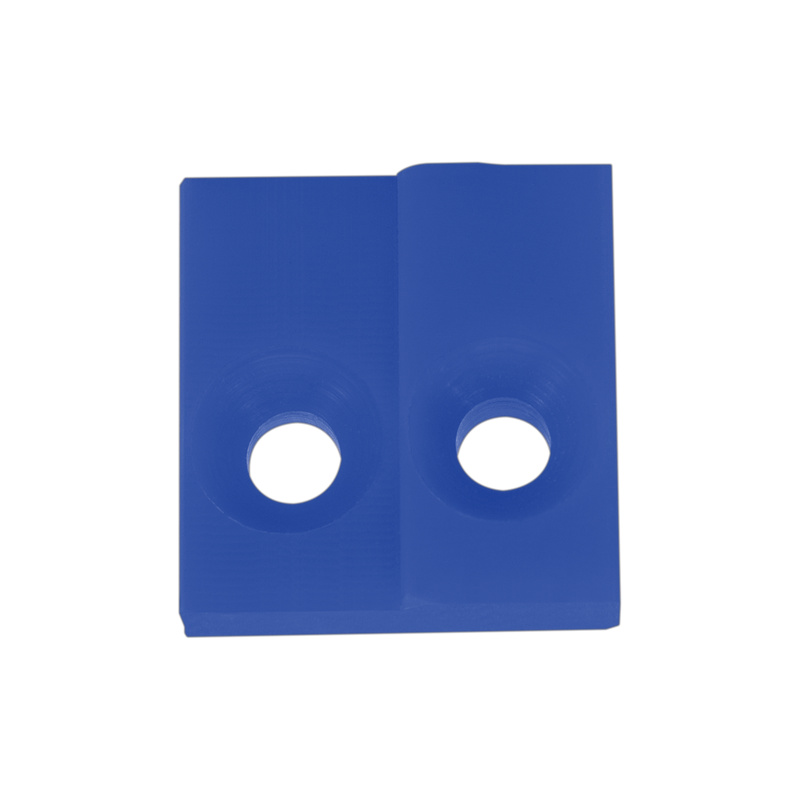

- Pneumatic locking device

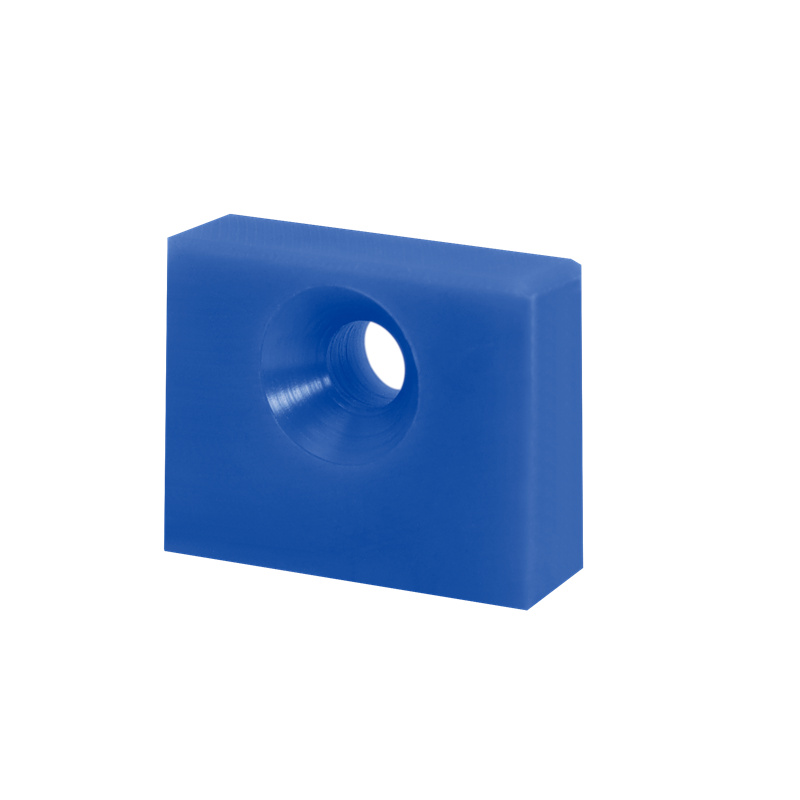

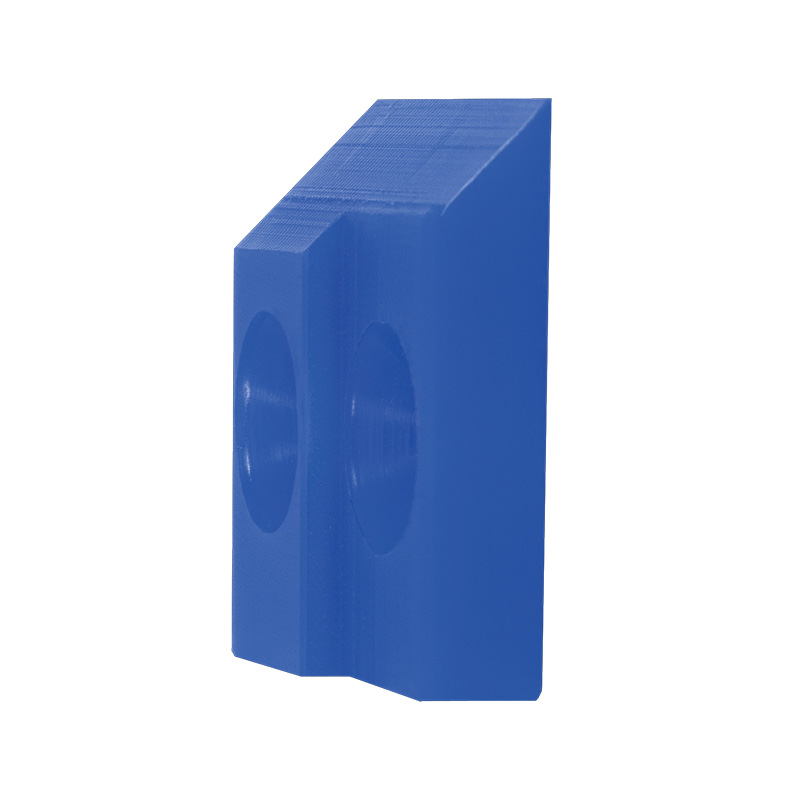

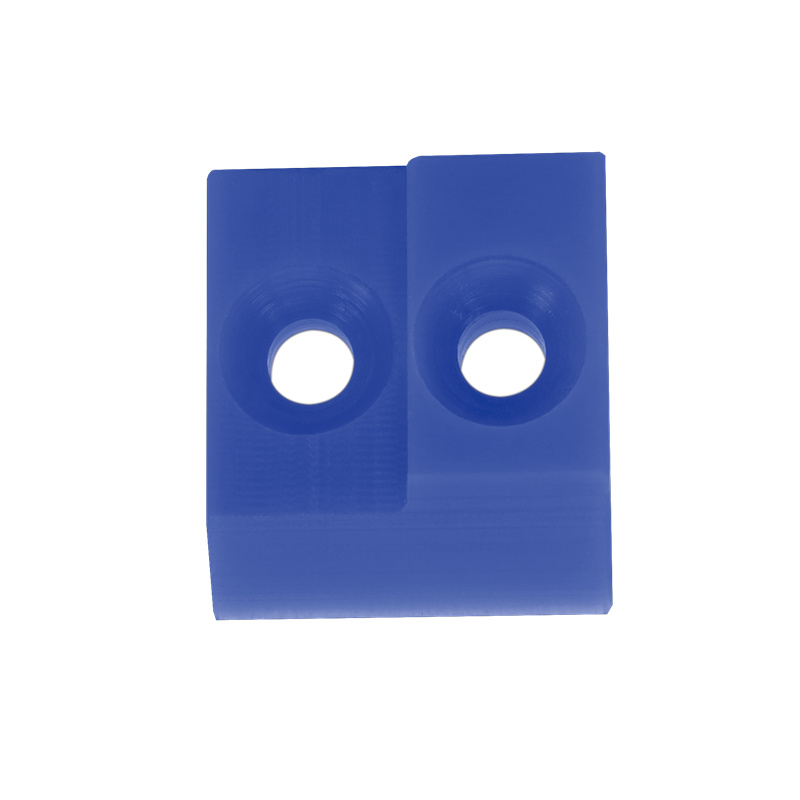

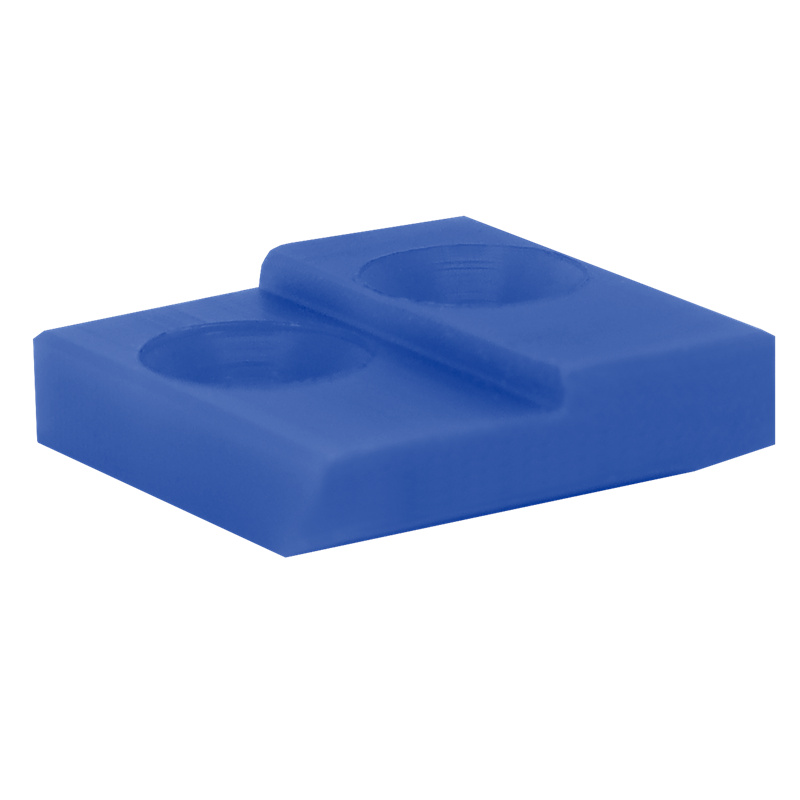

- Air cushion for cutting plate handling

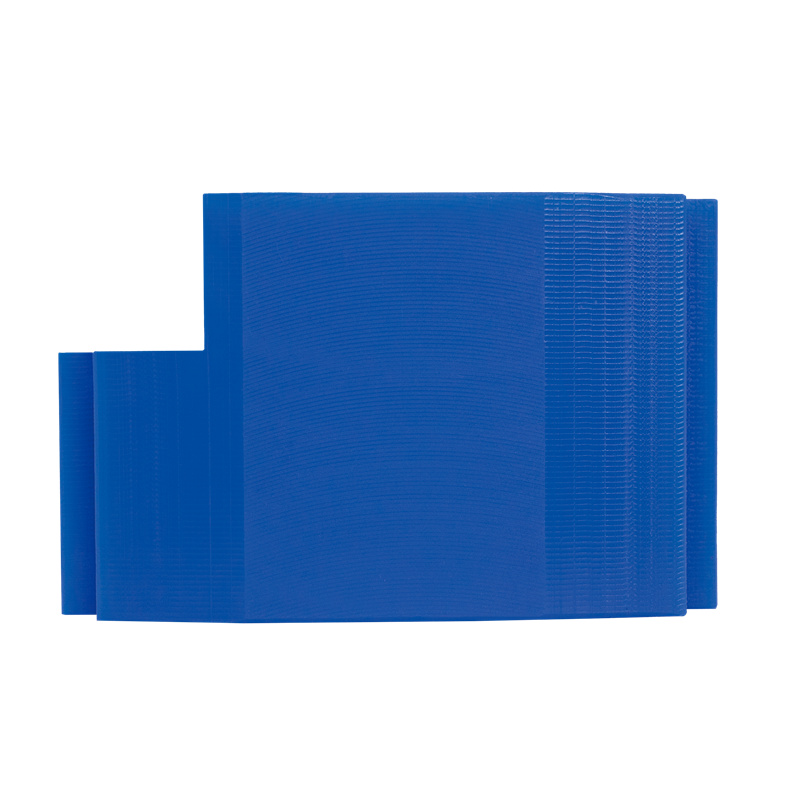

- Adjustable cutting plate

Stripping Unit

- Upper stripping frame pneumatic lifting device

- Stripping frame central positioning system

Delivery Unit

- Standard configuration:Gripper edge removal system and test sheet removal device

- Pile aligning device

- Pneumatic and motorized combined auxiliary delivery device can complete the non-stop delivery.

- There are two ways of delivery:high pile delivery mode and conveyor mode (The standard configuration is high pile delivery mode.After the delivery is completed,pull it out together with the pallet.)

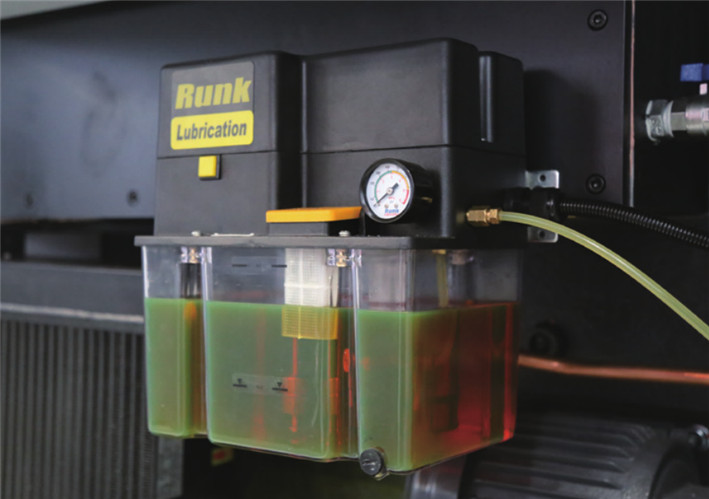

Lubrication System

- The main moving parts of the machine are lubricated by automatic lubrication system,which effectively reduces equipment maintenance time and extends equipment life.

Control and Safety Protection

- The imported pressure sensor detects the deformation of the plate.When the maximum pressure is exceeded,the machine will alarm and stop running.

- The modular design of the electrical control components makes maintenance simple and convenient.

- The machine electronic control design meets national safety standards,meets operational requirements,and optimizes control.

| Max. sheet size | 1300mmx960mm |

| Min. sheet size | 550mmx500mm |

| Max.die cutting size | 1300mmx945mm |

| Inner chase size | 1360mmx970mm |

| Gripper margin | 9-17mm |

| Sheet specification | 1-5mm(E、 B、C、A corrugated board) (The sheet flatness reaches the national standard GB-T 6544 2008. Each single comugated board warpage should not greater than 20mm) |

| Max.pressure | 200T |

| Max .speed | 6000s/h* |

| Max.feeder pile height | 200mm(down side feeder) |

| Max.delivery pile height | 1300mm(incl.pallet)(high pile delivery mode)180mm (counting stacking conveyor mode) |

| Main motor power | 11KW |

| Weight | ≈30000kg |

| Dimension | 7250mm(L)x3400mm(W)*2650mm(H) |

| Air source requirement | Pressure 0.6-0.7Mpa, Flow rate >0.8 m3/min |

| *Depending on the type of product, the speed and accuracy of the machine are different | |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Ecocut MK 130CS corrugated cardboard die cutting machine

In the world of modern packaging and design, the need for precision, speed and versatility is relentless. The cardboard die cutter is a revolutionary tool that not only smplifies the manufacturing process, but also opens up a world of creativity. If you're in the market for a corrugated cardboard die cutter, you're about to take your production to new heights.

Ecocut MK130CS cardboard die cutter operation process

The corrugated cardboard die cutter is designed to accommodate a wide range of corrugated box packages, including those specified by Royal Mail guidelines, paper boxes, medical packages, wine packages, food packages, and other environmentally friendly products. It incorporates various advanced features, such as micro-computer control, HMI interface, servo positioning, alternating current frequency converter, automatic counting, photoelectric rectifying, pneumatic lock cutting plate, electromagnetic clutch, centralized oil lubrication, overload protection, and distinctive gearing. These features ensure consistent pressure, precise positioning, smooth operation, and safe and reliable performance.

In the accompanying video, you can observe the automatic feeding of the board into the machine. Once inside, the board is die-cut using the cutting forme, and the resulting waste board is fragmented and removed through shaking. The waste board then travels along a conveyor belt and enters the waste extraction system for recycling. The fully stripped die-cut boxes are systematically stacked and palletized.

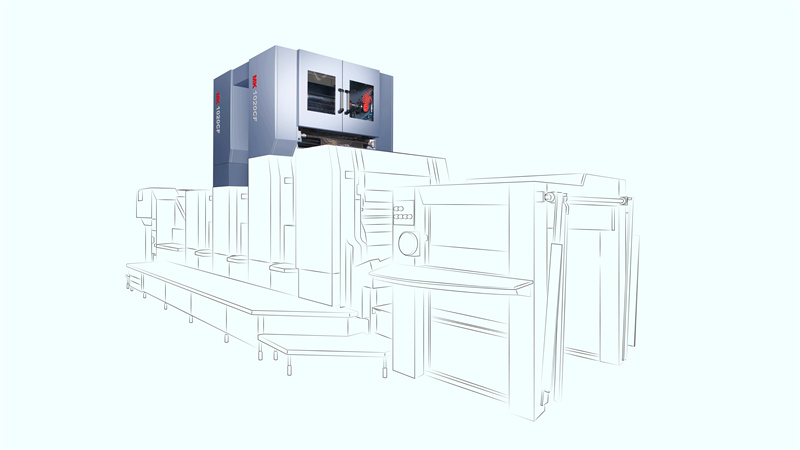

MK's small box die-cutting machine offers complete automation, encompassing automatic feeding, positioning, cutting, creasing, and collection. By utilizing JWEI's small box die-cutting machine, you can significantly reduce the time required for producing small E corrugated boxes while improving overall efficiency.

Advantages of cardboard die cutting machine:

(1) Redefine Efficiency: The cardboard die cutter automates the process of cutting complex shapes from cardboard, significantly reducing manual labor and production time.

(2) Precision and Consistency: These machines provide precise and consistent cuts, ensuring that each board meets precise specifications, which is critical for a polished end product.

(3) Best customization: Cardboard die-cutting machines allow you to bring complex and innovative designs to life, bringing unique advantages to your packaging and displays to stand out in the market.

(4) Material Versatility: These machines are designed to handle various types and thicknesses of cardboard, making them versatile tools for a variety of applications.

(5) Reduce waste: The accuracy of the cardboard die cutting machine can minimize material waste, which helps to save costs and protect the environment.

Ecocut MK 130CS cardboard die cutter is mainly suitable for medium-format corrugated cardboard with a width of 1300x960mm and a thickness of 1-5mm. It is a cardboard die-cutting machine with waste removal function.

MK has won many national honors and provincial awards, has a nationally recognized technology center, and can produce high-quality cardboard die cutting machines.

For more information about MK's cardboard die cutting machines, please contact us!

+

> Suitable for the following industries

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below