Feed Station

- The paper feeding unit adopts servo drive control to achieve precise synchronization with the host, and can also stop

- The front and rear positions of the feeder head and the side blower can be automatically adjusted according to the work order data (Master Feeder)

- Auto pile correction

- Automatic and electric adjustment of the feeder head height increases convenience of operation and reduces labor intensity

- Ultrasonic double sheet detection

- The third-generation mechanical double-sheet detection device has higher stability, convenience and flexible operation

- Integral adjustable pinch roller frame

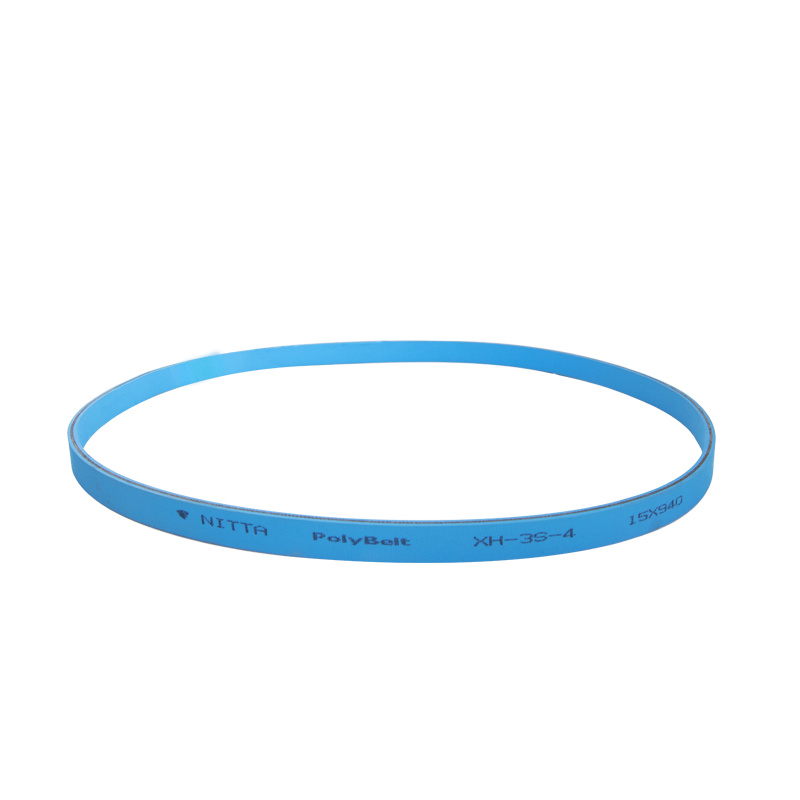

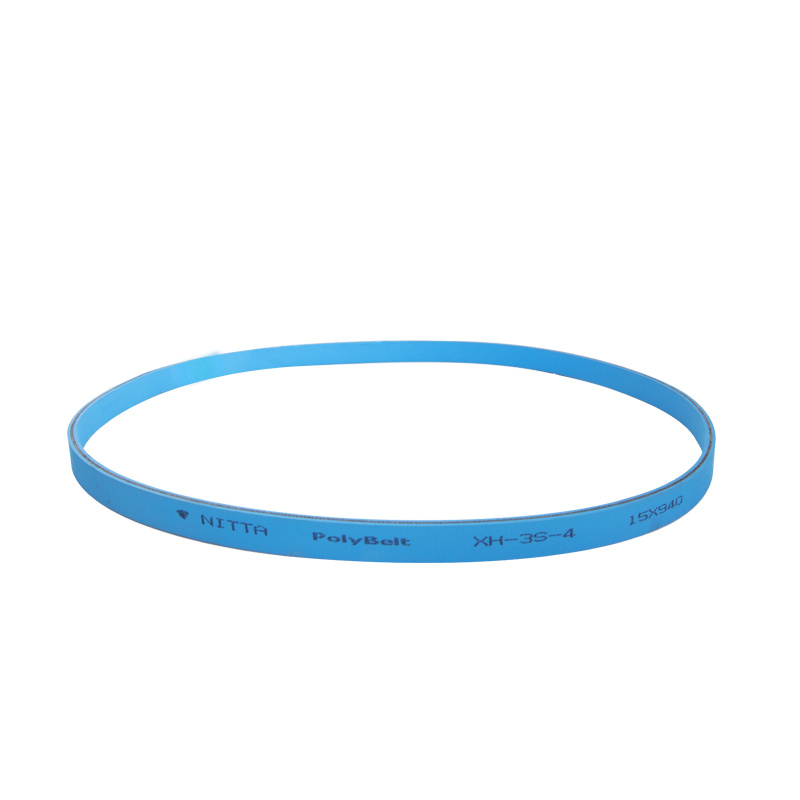

- Servo drive main and auxiliary paper feeding

- MasterSet Electronic registration system

- Adaptable to European standard 1200x800mm tray

- Fully Automatic Master Feeder (Optional, used with Feeder Logistic)

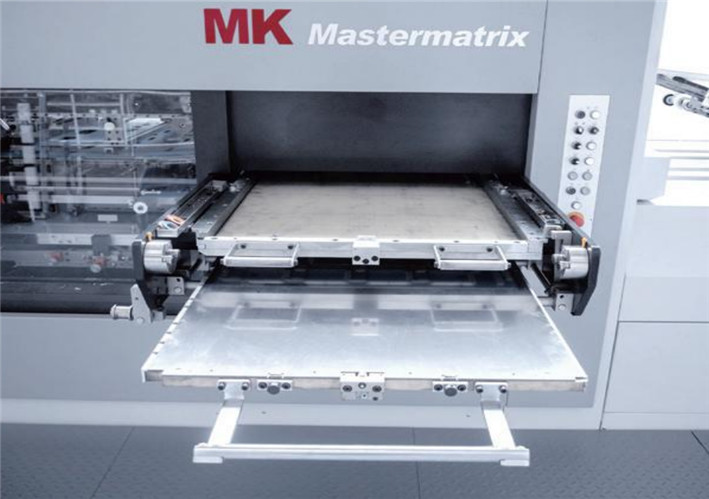

Cutting Station

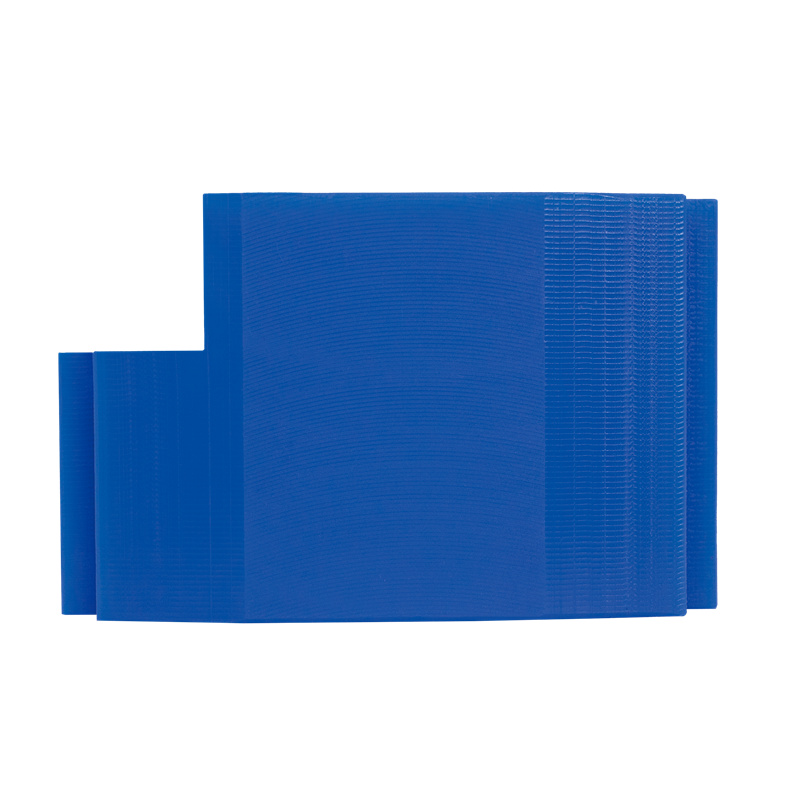

- The new generation main engine structure, high-speed motion curve, and stable main engine oil temperature control system provide more stable die-cutting pressure for high-speed production

- The use of a large angle divider allows paper to run more smoothly

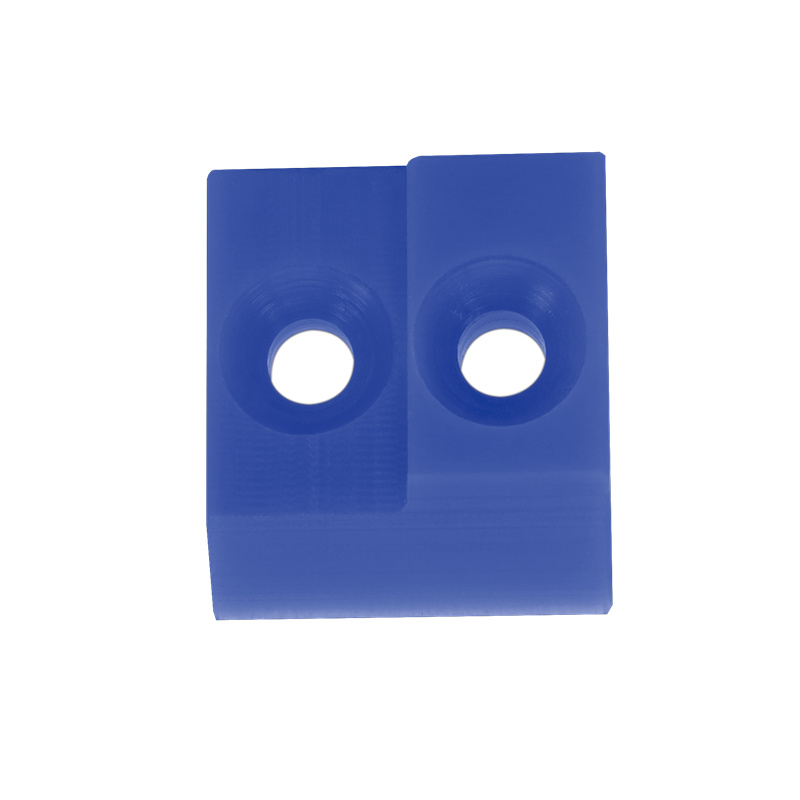

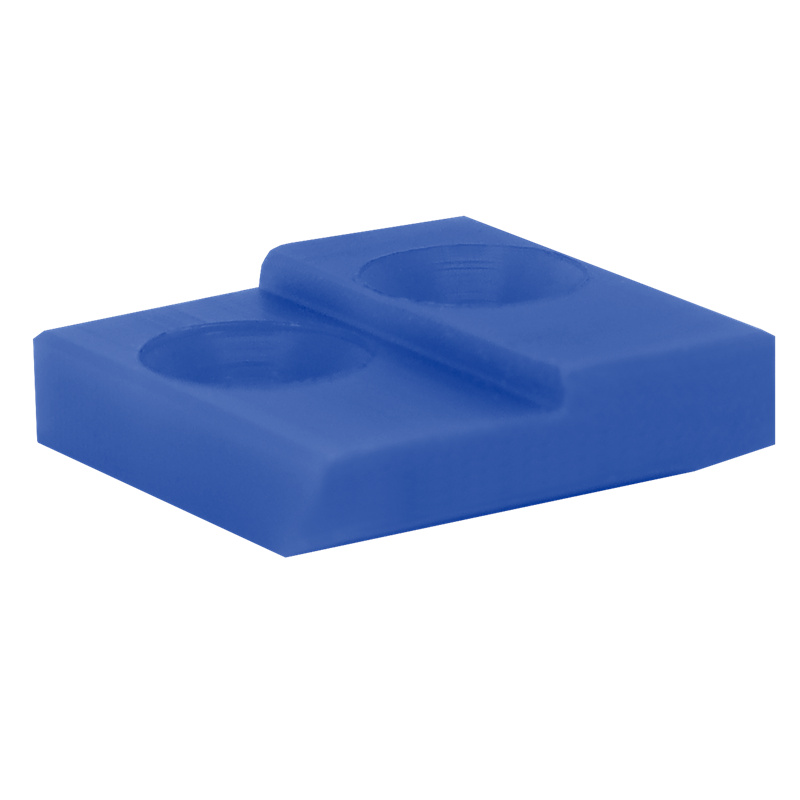

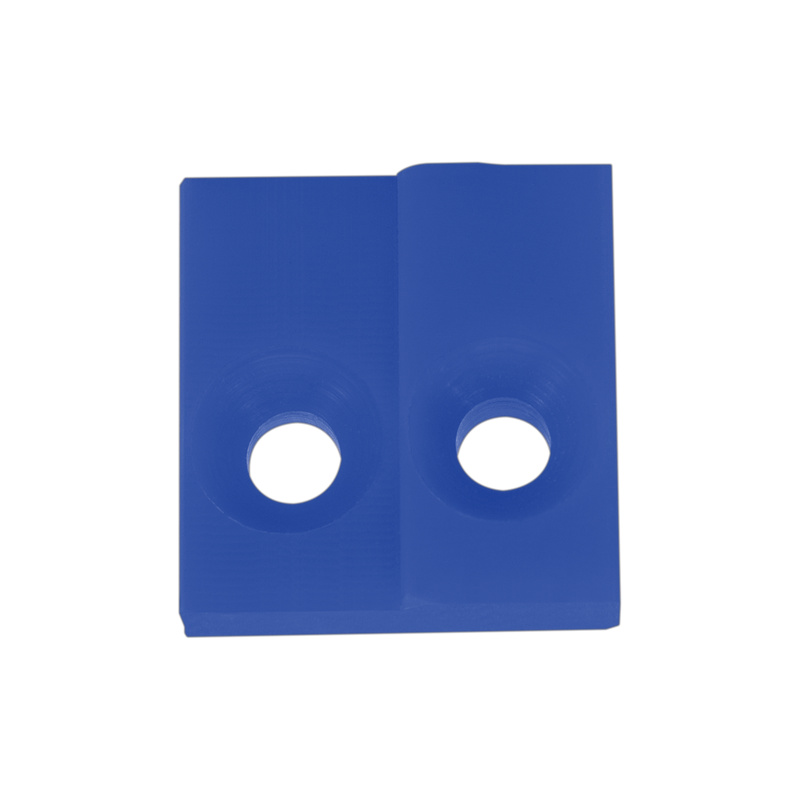

- The bottom plate of the new resin quick lock makes operation easier and faster

- The new steel plate quick-lock mechanism provides higher plate changing efficiency

- If paper is not in place then diverts to forced opening and paper clamping system

- Servo automatic pressure regulating system

- Tool-less one-key two-way pneumatic locking device

MasterSet

- Adopt high-speed, high-precision image and phase sensor

- Can detect color mark, printing pattern, paper edge and other modes

- Using servo control system to achieve high-precision registration of paper

- Large amount of automatic deviation correction and wide adaptability, greatly reducing downtime probability

- The use of non-contact paper conveying avoids scratches on the surface of the paper

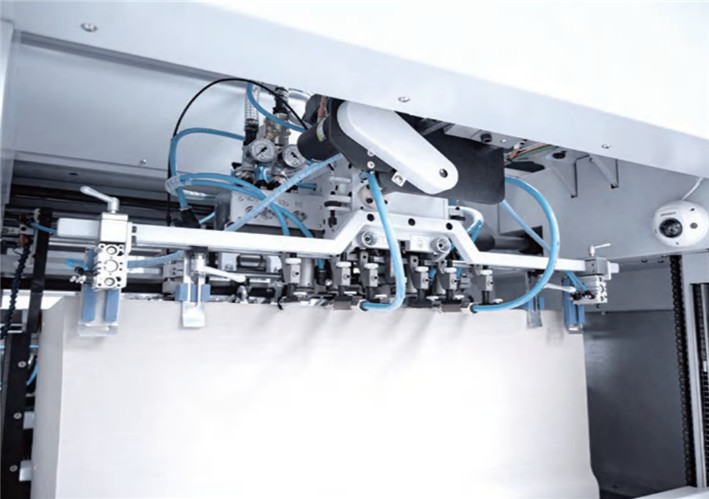

Stripping Station

- More accurate and convenient second-generation waste removal tool quick lock system

- Fine-tuning device with digital display

- Waste removal tool centering system

- Pneumatic lifting device for cleaning the upper frame

- The new generation suction plate device allows paper to run more smoothly and stably at high speed

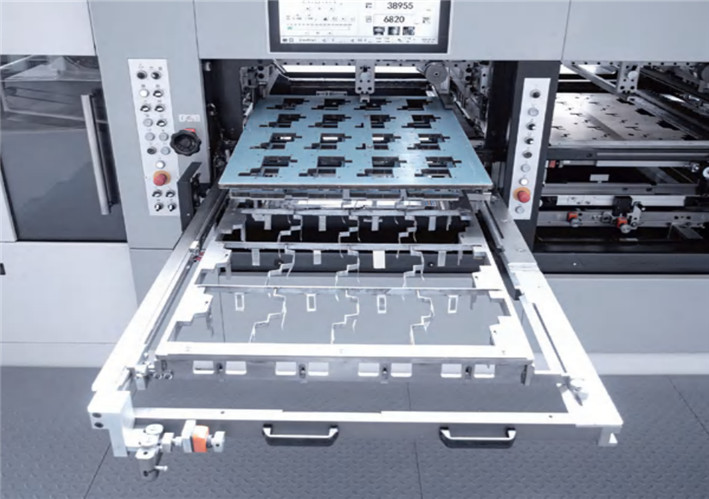

Blanking Station

- Box tool quick lock system

- Fine-tuning device with digital display

- Box tool centering system

- Pneumatic lifting device for upper frame of sub-box

- Automatic paper laying counting device

- Automatic non-stop delivery device

- The automatic discharge device can meet the European standard 1200x800mm tray

- The new generation of suction plate device allows paper to run more smoothly and stably at high speed

Test Sheet Removal

- Waste edge conveying device

- Non-stop sampling device

- Servo driven damping brush control system

Control System

- IPC industrial computer control system, industrial interconnection interface, can connect to Heidelberg Prinect system

- 21.5 inch double large size true color touch human-machine interface

- Production order recipe management function, support fast switching

- Video recording monitoring system, support recording, playback, screenshot function (optional)

- Production operation data statistics function

- Intuitive and concise interface and operation panel

- Whole machine GS certification

- Masterwork cloud service, with remote diagnosis, monitoring and maintenance functions

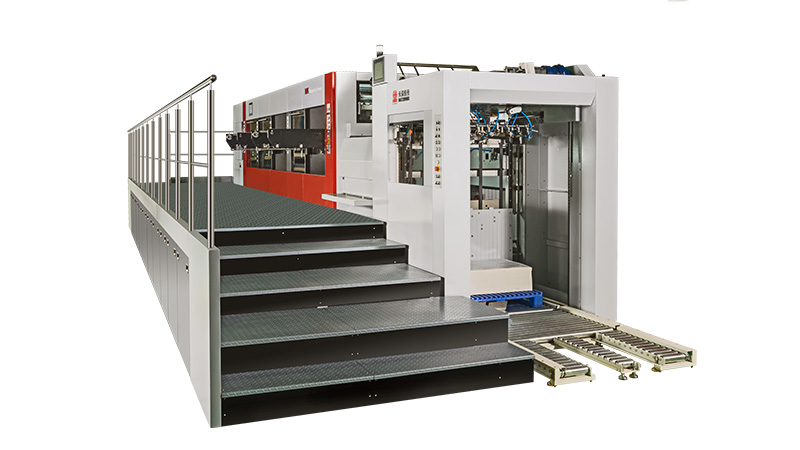

| Maximum paper size | 1060mmx760mm |

| Minimum paper size | 400mmx350mm |

| Maximum die cutting format | 1060mmx745mm |

| Inner width of the frame | 1096mmx770mm |

| Mouth blank | 9-17mm |

| Paper size | 90~2000g/m2 (0.1~2mm) paper or solid cardboard ≤2mm(corrugated paper: flatness less than 20mm/m2) |

| Maximum working pressure | 260 ton |

| Maximum working speed | 9000 pieces/hour |

| Paper stack | Up to 1800mm (including tray) |

| Delivery stack high | Up to 1500mm (including tray) |

| Main motor power | 15KW |

| Full load power | 40KW |

| Total Weight | 22ton |

| Overall dimensions | 10.20m (length including foot pedal) x6.16m (width including foot pedal, electrical cabinet) x2.94m (height) |

| Air source requirements | 0.65-0.7Mpa,>0.8m3/min |

| *The speed of the machine varies depending on the product type. Subject to R&D data | |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

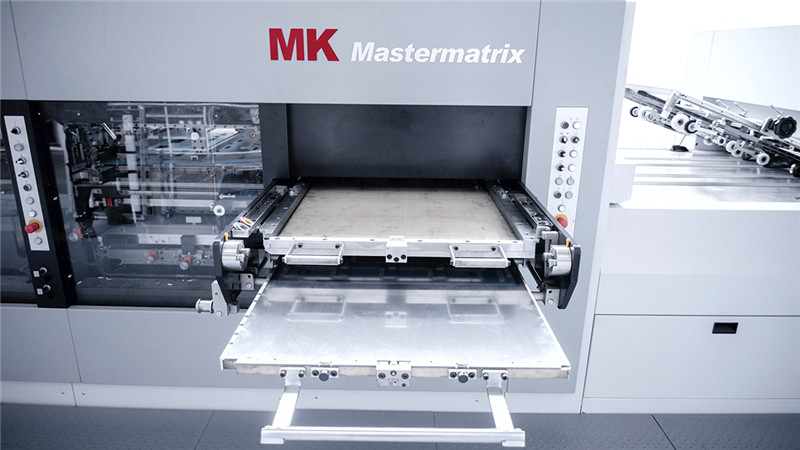

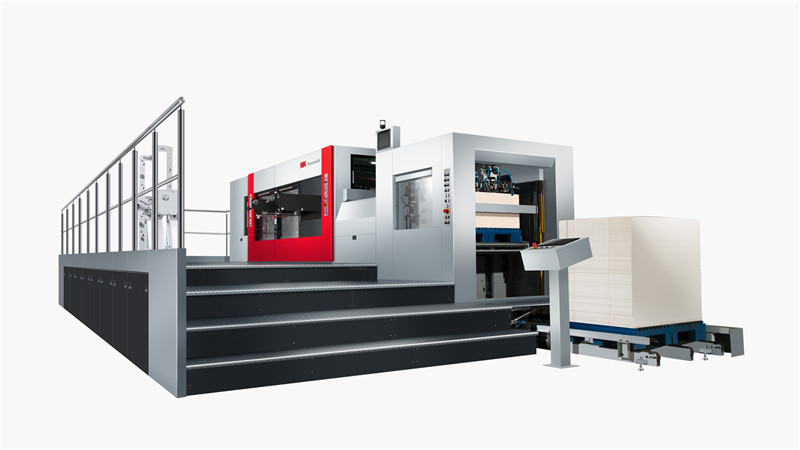

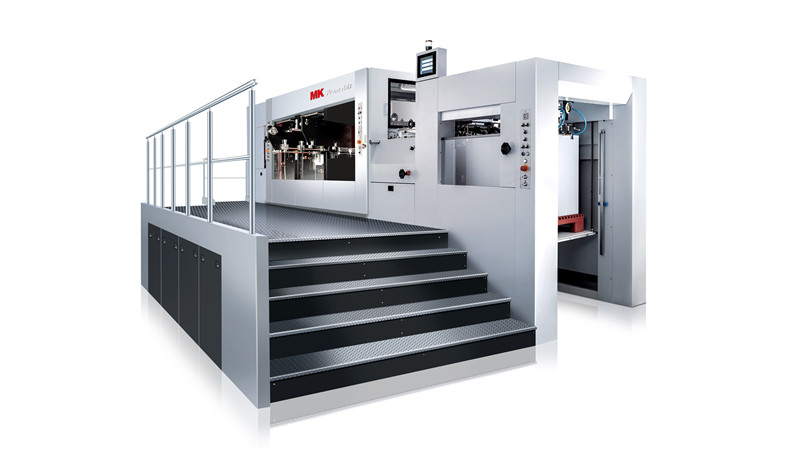

Automatic Cardboard Die Cutting Machine

MasterMatrix 106CSB is a ultra -intelligent fully automatic cardboard die -cutting machine, known for its excellent automation, intelligence, speed and reliability.

Designed to meet the needs of customers with high intelligent production and high capacity!

If you are interested in our fully automatic cardboard mold cutting machine, you can contact us!

It allows fast operation. With its unique cutting system, cam drive system, and optimized fixture curve motion to achieve an amazing speed of 9,000 (9000s/h) per hour, handle cardboards in an efficient way!

This product has feed stations, cutting stations, masters sets, divestitudes, removing stations, removal of tested films, and control systems. MasterMatrix 106CSB can cut the maximum paper size of 1060mm × 760mm, the smallest paper size is 400 mm × 350 mm, and the mold cutting surface reaches 1060mmx745mm.

MK is one of the leading China Automatic Cardboard Die Cutting Machine manufacturers, suppliers and exporters, our Automatic Cardboard Die Cutting Machine has high performance and competitive price, perfect after-sales service!

+

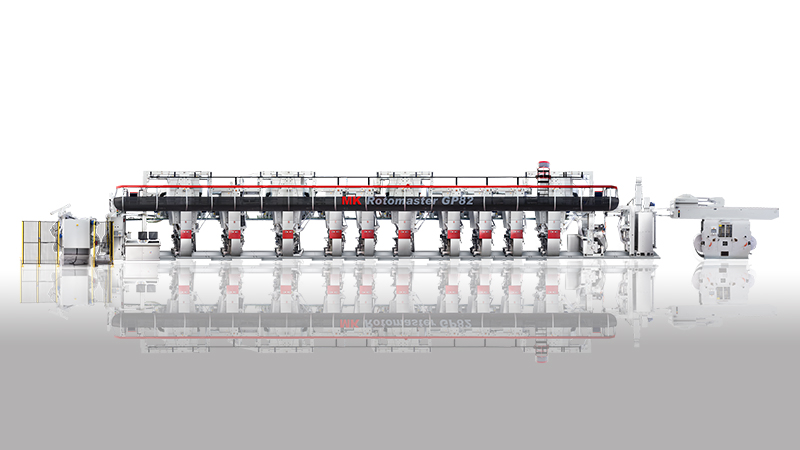

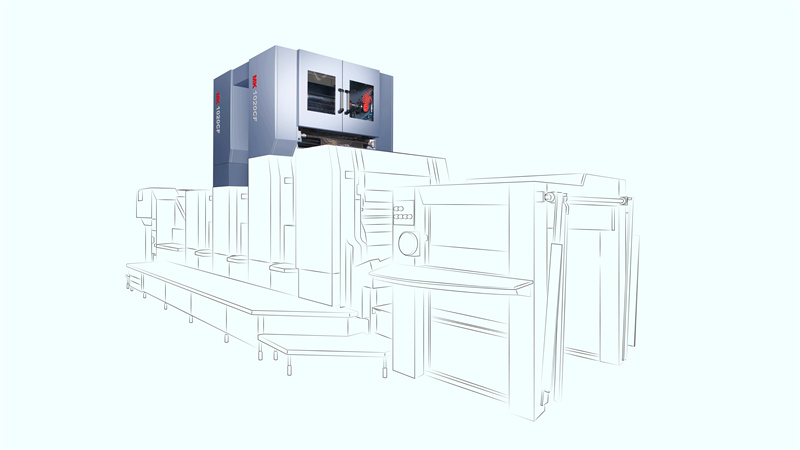

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below