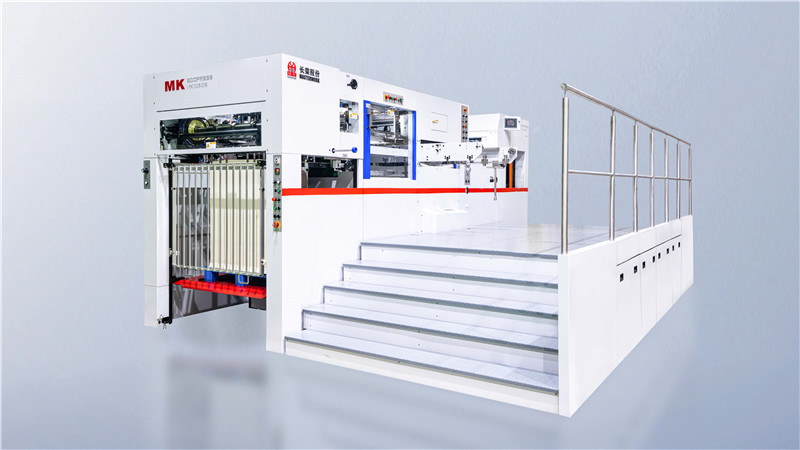

Infeed unit

- Imported aluminum alloy feeder; adjustable suction tube

- 3 feeders anti-collision devices

- Strong sheet suction feeder, with 4 suctions and 4 deliveries

Feeding table

- Driven by chain movement,with stable and reliable operation

- The same as high-end models,with integral adjustable sheet feeding frame and sheet feeding accessories

- Improved slowdown device,with more stable structure

- Equipped with sheet feeding detection and control system,reducing waste

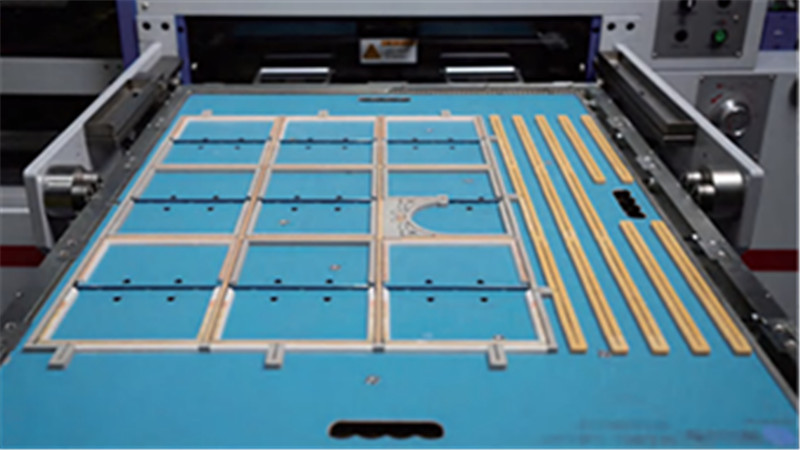

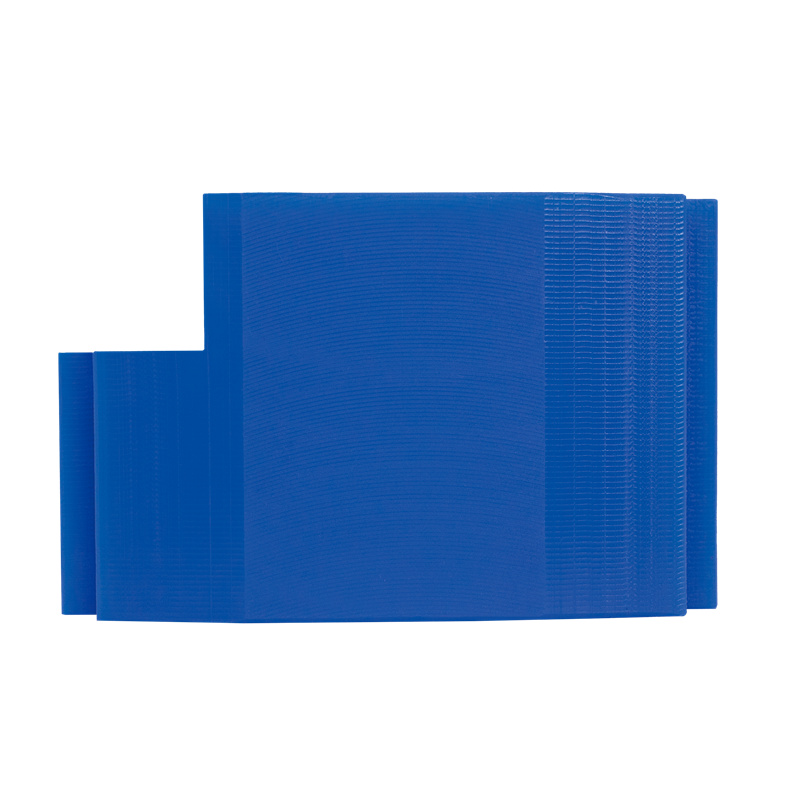

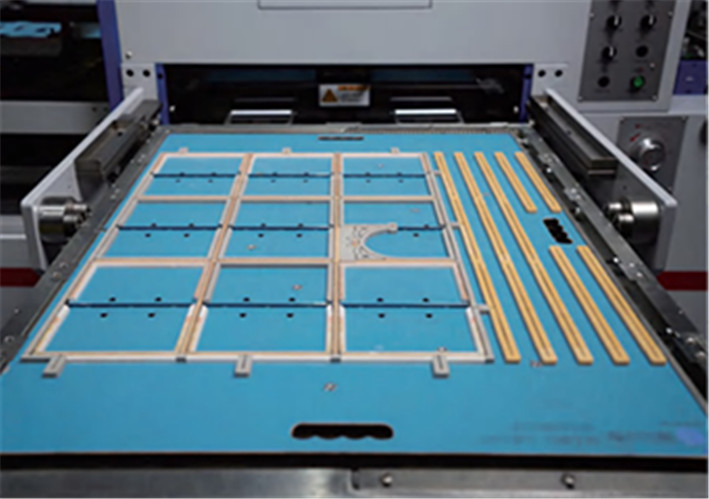

Die Cutting unit

- The complete set of worm gear and worm from Taiwan to improve the service life of key transmission parts of the machine

- The wallboard and base of main machine should be the resin sand ductile iron cast by British dense baking grade to ensure long-term reliable and stable operation of the whole machine

- Stay stable when bearing large tonnage pressure

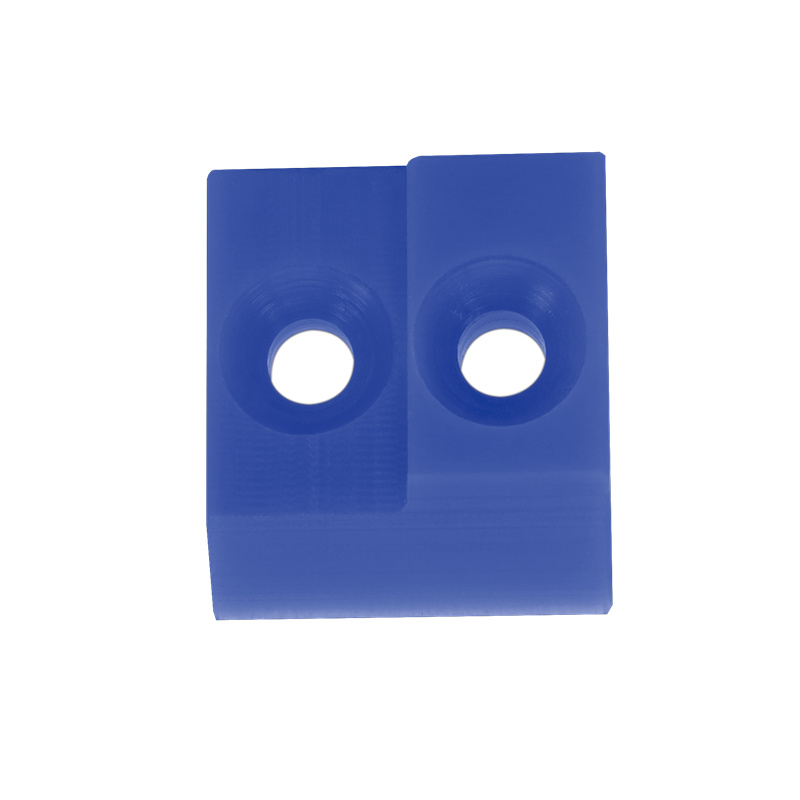

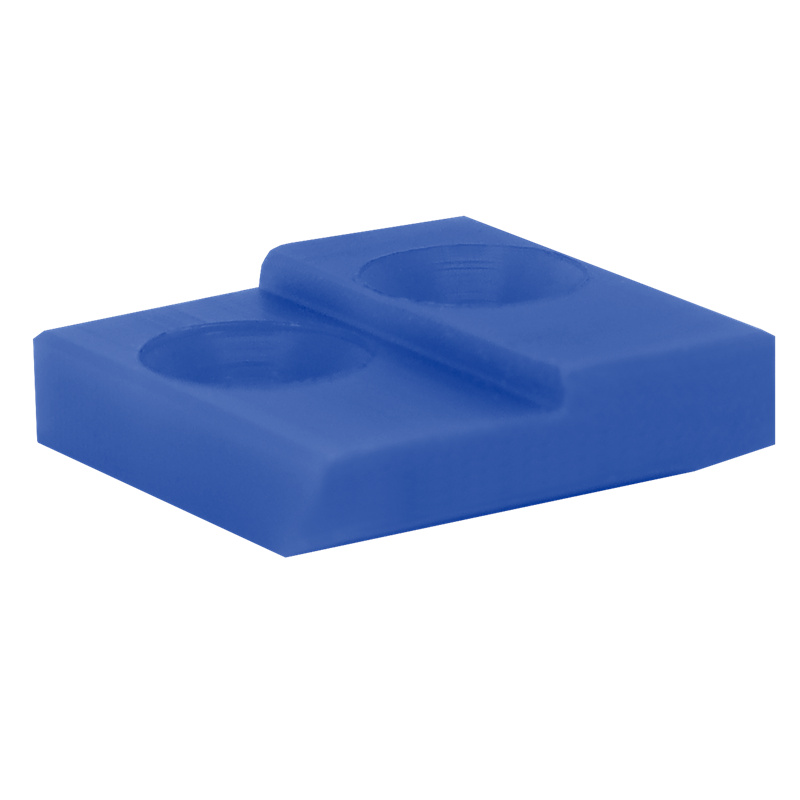

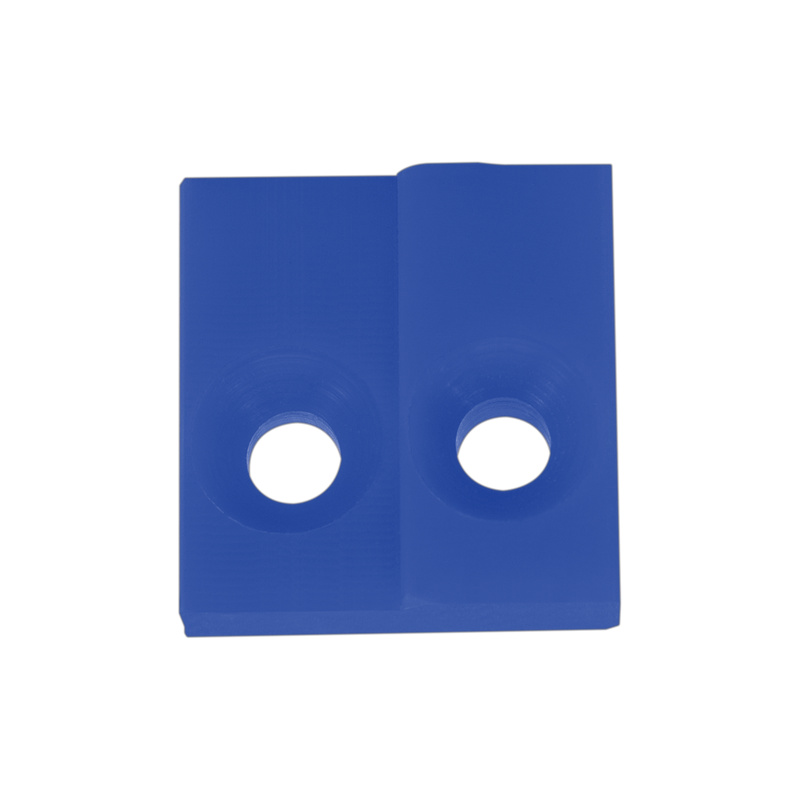

Stripping unit

- Classic and efficient stripping structure

- Central positioning system

- Upper stripping frame lift-up device

Delivery unit

- Mechanical collection and pressing brush for damping and deceleration

- Bidirectional auxiliary blowing for collection

- Pneumatic sampling mechanism

Control system

- Designed by EU CE standard and equipped with high-grade European brand circuit safety module

- Equipped with double-loop safety protection detection device,which makes detection more stable,accurate and safe

- Imported electrical components

| Maximum sheet size | 1050mmx750mm |

| Minimum sheet size | 400mmx360mm |

| Maximum die cutting size | 1040mmx740mm |

| Inner chase size | 1120mmx779mm |

| Sheet specification | 90~2000g/m2 or 0.1~2mm paper or cardboard ≤4mm corrugated board (flatness <20mm/m2) |

| Maximum pressure | 250T |

| Maximum speed | 7500s/h |

| Maximum feeder pile (including pallet) | 1150mm |

| Maximum delivery pile (including pallet) | 1000mm |

| Main motor power | 11KW |

| Total weight of the machine | 17T |

| Dimension (L*W*H) incl.catwork | 5800mm x4080mm x2050mm |

| Air source requirement | 0.55-0.7Mpa,≥0.37m3/min |

| *The speed and accuracy of the machine will vary with the type of product. | |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

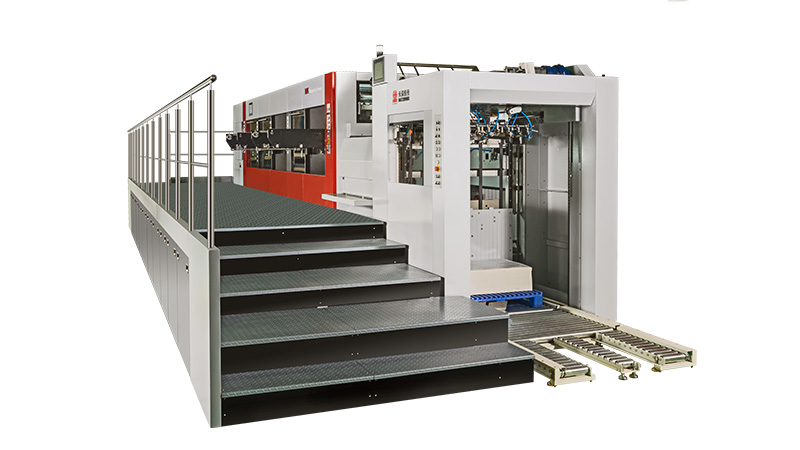

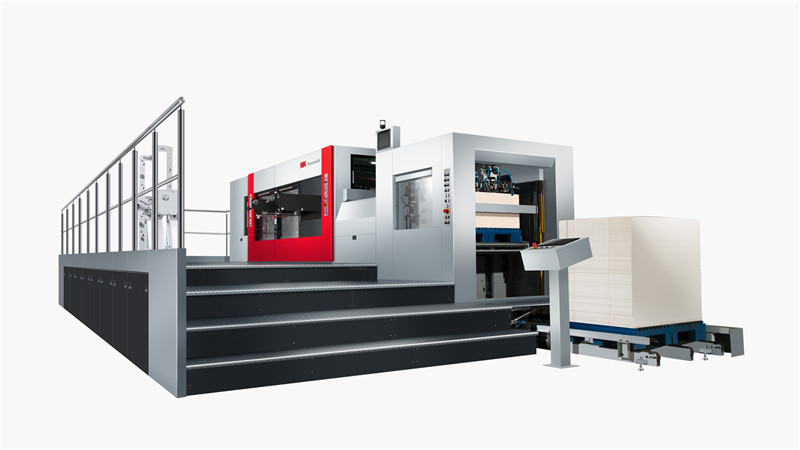

ECOPRESS MK 1050E cardboard die cutter supplier

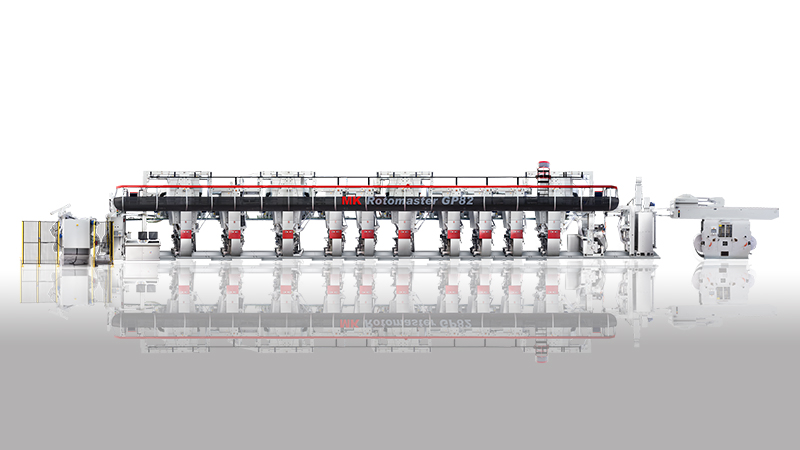

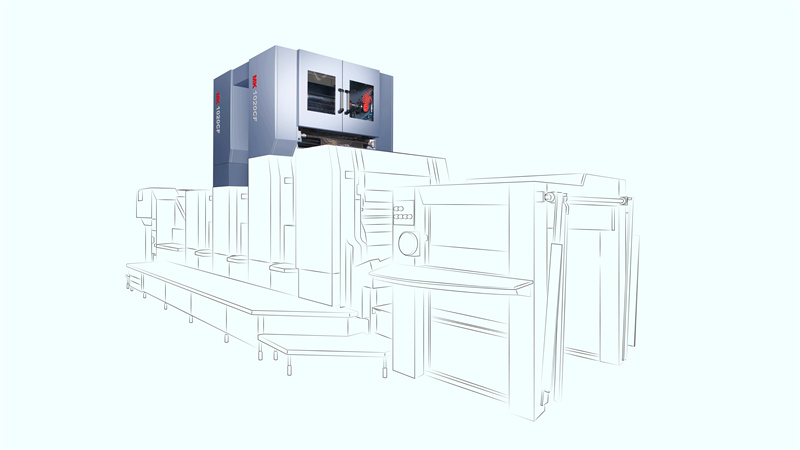

As a leading supplier of advanced cardboard die-cutting equipment, MK is at the forefront of technological excellence with an impressive array of proprietary technologies and a multi-patent portfolio. Committed to staying ahead, MK is a steadfast partner to customers, supporting both established and emerging technology areas.

ECOPRESS MK1050/E waste removal die-cutting machine is an economical and affordable equipment designed for the majority of printing and packaging companies. It stands out in the fierce market competition and has the ability to respond quickly and work with high precision. Our goal is to reduce costs and improve production efficiency, and the ECOPRESS MK1050/E scrap die-cutting machine has always adhered to high quality standards. We go all out to provide you with better and attentive services to ensure that you don't have to worry about anything.

MK is committed to prioritizing the best interests of its clients, employing innovative management methods to promote sustainable development. Underpinning this commitment is an unwavering commitment to delivering solutions that seamlessly fit our clients' unique needs and desires.

A sign of MK's operational strength is the establishment of an advanced information management platform. The platform is firmly based on the integration of auxiliary intelligent management units, such as ERP and MES systems. Through these interconnected systems, real-time data collection, meticulous documentation, comprehensive review and collaborative oversight of each operational step are seamlessly coordinated, resulting in an environment of unwavering operational stability and unparalleled efficiency.

By utilizing cutting-edge technology and customer focus, MK pushes the world of paperboard die-cutting equipment toward new possibilities. In its pursuit of excellence, the company continues to pave the way for a future where innovation, precision and sustainable growth seamlessly blend.

We usually grow by thinking and practicing accordingly according to changes in the environment. Our goal is to realize a richer mind, body and life for cardboard die-cutting machines. Are you still looking for a quality product that matches your outstanding corporate image while expanding your range of solutions? Try our great products. Your choice will prove to be a wise one! If you would like to know more details about our company, please contact us today!

+

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below